Services

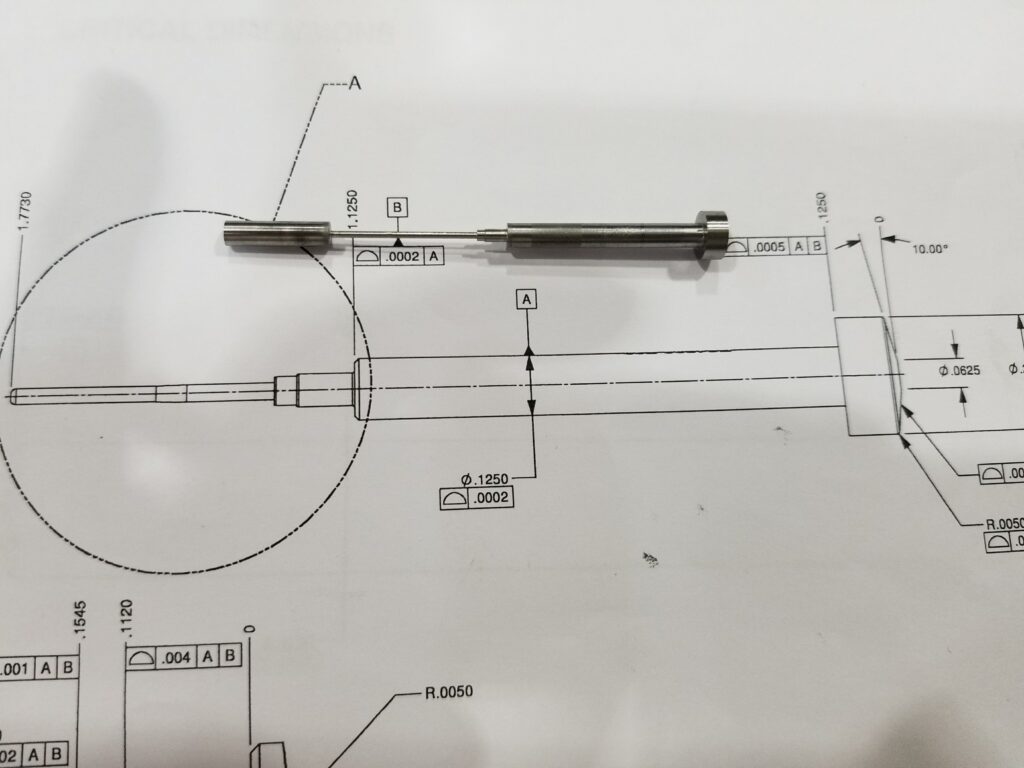

Ultra-Precision Machining

We offer a full complement of machining capabilities to take your parts from concept to reality. We provide some of the most intricate and demanding services available in the manufacturing and grinding industry. Thanks to our advanced skills and technologies, there are few components our ultra-precision machining team cannot handle. We’re here to make the impossible possible.

Our ultra-precision machining capabilities include:

- Vertical machining (milling)

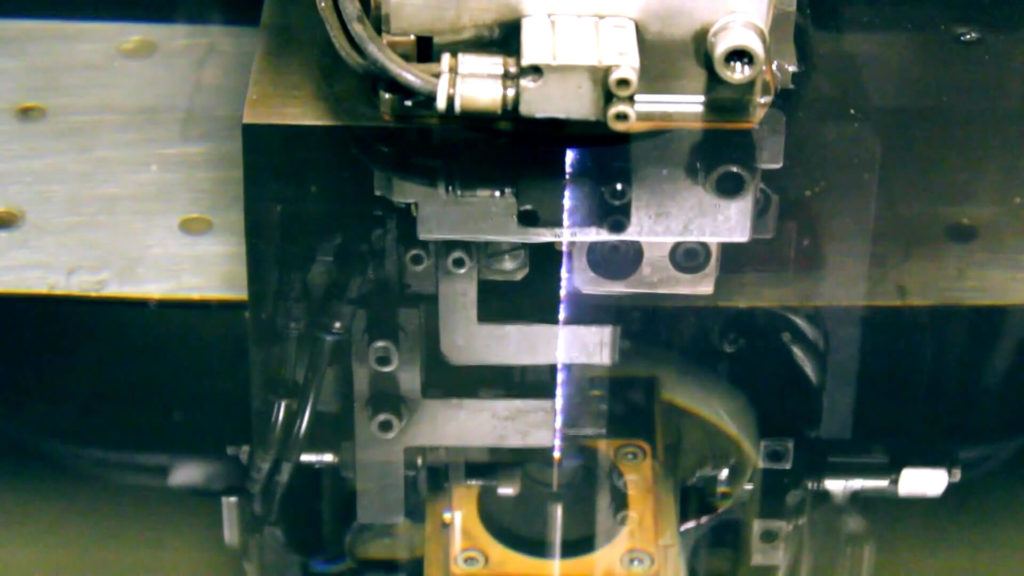

- Wire EDM

- Ram EDM

- Swiss screw machining

- Micro-machining

- Milling/turning

- Toolmaking

Benefits of our ultra-precision machining services:

- Exceptional quality and accuracy with timely delivery

- Direct and open communication from engineering and quality control teams

- High-touch customer service process with routine status updates

- Urgent attention with same day service and expedited US and international shipping

- Secure data and file maintenance for easy reorders

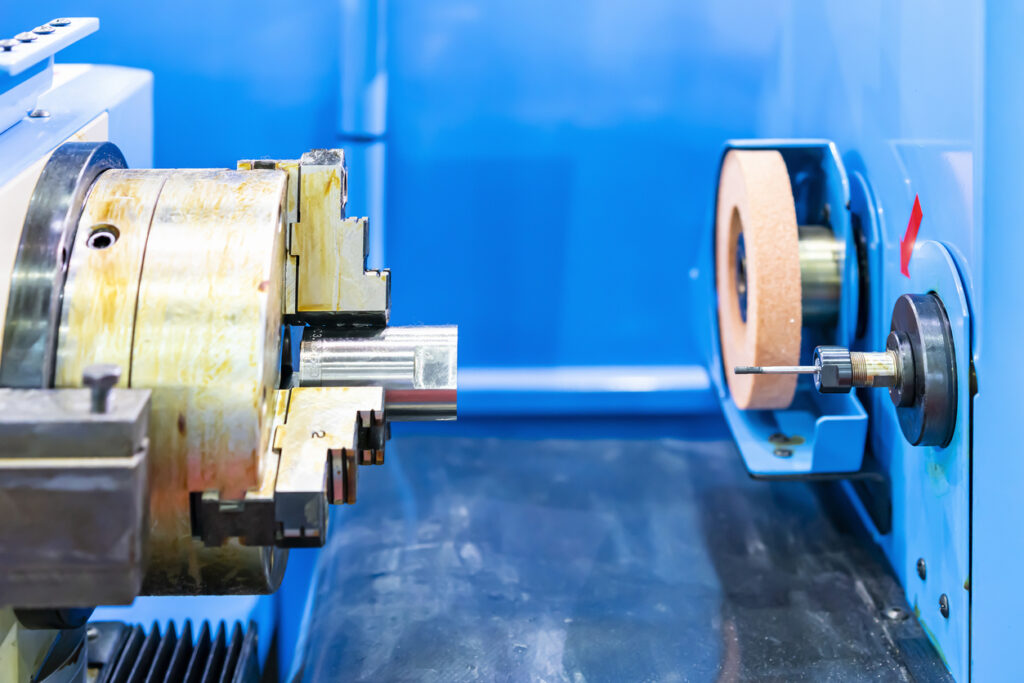

Ultra-Precision Centerless Grinding

Our ultra-precision centerless grinding capabilities flawlessly complement our expert machining skills, allowing us to take your highly exacting project to completion under one roof. We have all the tools to execute a plan to meet your most demanding needs with speed and accuracy, from single-operation grinding services to dock-to-stock part production. Every day, we grind sub-micron tolerances on diameters, complex geometries, and intricate part features previously thought unattainable. When there is no margin for error, choose us to get it right, or we’ll make it right.

Our centerless grinding capabilities include:

- Ultra-precision centerless

- Precision centerless

- Hybrid CNC centerless

- Guidewire centerless

Benefits of our ultra-precision centerless grinding services

- Smart, innovative component manufacturing solutions for complex parts and materials

- Responsive R&D/developmental projects and dependable long-run production work

- Same day service for tight timelines with UPS-red shipping in the US and internationally

- Effective communication with engineers, quality control, and project management teams

- Peace of mind that your precious asset is in safe and capable hands

Engineering services

We offer consultative engineering services – a time- and money-saving core strength that is difficult to overvalue. Expect our engineering team to blend seamlessly into your organization as you work your way through the developmental process, providing critical support to help you succeed.

Third-Party Process Management

We manage secondary outside processes as part of our wide array of production capabilities, making for a streamlined component manufacturing experience. In addition, our project and vendor management teams integrate the capabilities of critical vendors to provide a convenient single point of contact.

The third-party processes we manage include:

- Plating & Coatings

- Heat Treatments

- Type I, II, III Anodize

- Chem Film

- Laser Welding and Cutting

- Additive Machining (3D Printing)

Dedicated R&D Resources

When it comes to meeting rigorous R&D demands, it’s not a pipeline of viable projects that fuels our perseverance to rise to a challenge. Instead, it’s the thrill of the breakthrough and the knowledge that we’ve achieved what others said could not be done.

- For decades, we’ve solved perplexing manufacturing challenges across every high-tech industry and are ready to do the same for you.

- Our R&D Lab supports all your engineering needs, from feasibility and prototyping to validation and full production.

- Gain access to dedicated equipment and passionate people committed to solving your biggest machining and grinding conundrums to expedite your timeline and save costs.

Our dedicated R&D resources include:

- 5-Axis Milling

- 10-Axis Swiss

- Surface Grinding

- Hybrid Centerless

- Guidewire Grinding

- EDM (coming soon)

ISO 14644 Class 8 Cleanroom

More than ever, a higher standard of quality and cleanliness is needed to manufacture medical components. In our ongoing quest for excellence, we’ve invested in an ISO 14644 Class 8 cleanroom to ensure your high-precision parts meet your rigorous requirements. Located in the Quality Control (QC) area of our facility, our cleanroom functions as the final stage of cleaning and packaging, eliminating a cleaning step downstream to save you time and money.

Additional Capabilities

Our passion for excellence doesn’t stop with our industry-leading machining and centerless grinding services. We also provide the full spectrum of manufacturing services to support your needs. Whether we’re machining, grinding, or performing one of our many additional capabilities, we’re achieving extraordinary feats every day. We’re continually trailblazing solutions that stray from the conventional in favor of the exceptional.

Our additional capabilites include:

- Custom tooling & fixtures

- Assembly & welding

- Nitric & citric passivation

- Gear hobbing

- Chemical processing