Choosing a Precision Grinding Partner

Choosing a precision grinding partner goes beyond reviewing a drawing and receiving a quote. Successful grinding outcomes are shaped early, during the first technical conversation, when material condition, tolerances, surface finish, and inspection requirements are evaluated before assumptions turn into risk. This early technical review helps sourcing and production teams protect cost, quality, and delivery once production begins.

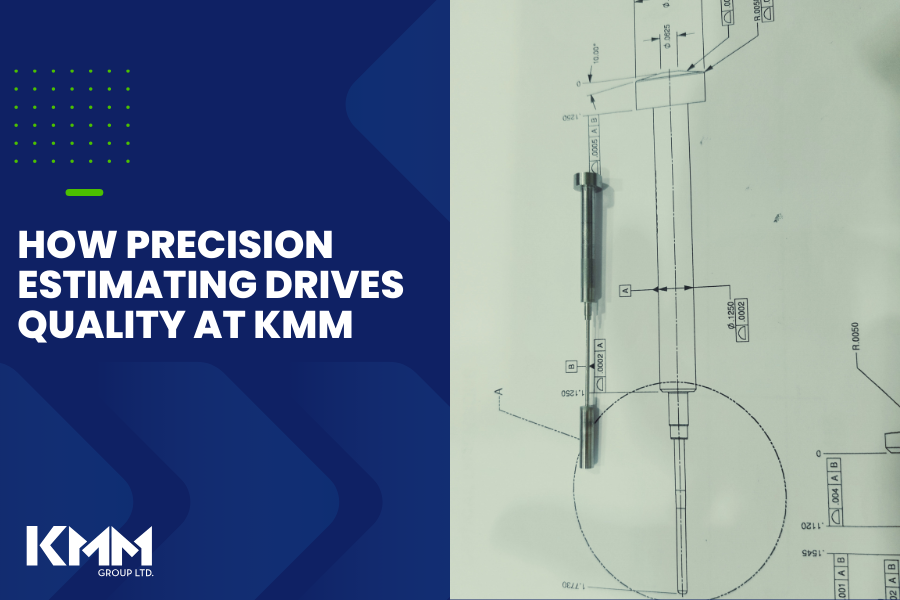

How Precision Estimating Drives Quality at KMM

Quality at KMM begins long before a part reaches the shop floor. Estimator Joshua Brodbeck uses decades of grinding experience to predict risks and ensure every job starts with accuracy and confidence.

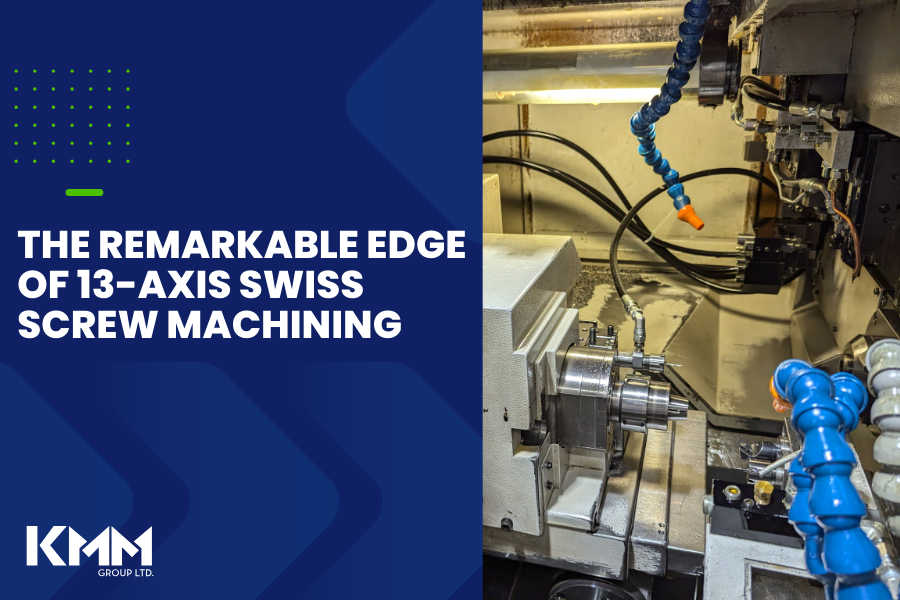

The Remarkable Edge of 13-Axis Swiss Screw Machining

The manufacturing landscape is evolving fast. Designs once considered “too complex to machine” are now standard requests. As components get smaller and performance requirements grow tougher, traditional machining centers struggle to keep up. The smarter move? 13-axis Swiss screw machining, which delivers the accuracy, flexibility, and efficiency modern programs demand.

Why a Balanced Supply Agreement Matters: A CMOs Perspective

When a supply agreement is written with mutual respect, it sets the tone for innovation, agility, and long-term partnership. When it’s written to control, it quietly undermines trust before the first part ever ships.

A Practical Guide to Class 8 Cleanrooms in MedTech Manufacturing

MedTech products, especially those used in sensitive medical applications, require an environment that meets strict quality standards. This is where Class 8 cleanrooms come into play.

7 MedTech Quality Control Pitfalls and How to Avoid Them

Quality control (QC) in MedTech manufacturing is a balancing act—ensuring precision, meeting regulatory standards, and keeping production on schedule. But even with the best processes in place, small oversights can lead to inefficiencies, rework, or delays.

5 Expert Tips To Secure A Reliable MedTech CMO Partner

In the high-stakes world of MedTech, the contract manufacturing organization (CMO) you choose could be the game changer your project needs. While large, multi-million-dollar CMOs may seem like the obvious choice due to their extensive resources and infrastructure, smaller, boutique CMOs can sometimes be an even better option.

Corewire Grinding Essentials: 7 Tips for Precision and Success

The Crucial Role of Corewire Grinding Precision corewire grinding is an intricate process in manufacturing the building block of medical guidewires. This process enables the creation of ultra-thin diameters and intricate configurations used in life-saving procedures. This specialty medical wire is essential for providing a delivery platform through the body’s blood vessels for advanced neurovascular […]

Employee Spotlight: Steve Dierkes – A Journey from Percussion to Precision

When Steve Dierkes joined KMM Group over a decade ago, he didn’t arrive with dreams of a manufacturing career. In fact, he started out as a percussion major at Kutztown University, without much knowledge of the world of grinding. But what started as a necessity—a job secured through a close friend—quickly evolved into a passion […]

Complex Precision Parts Simplified: The Magic of Wire EDM

Wire EDM is an advanced precision manufacturing process that unlocks endless possibilities for creating intricate geometries and fine details in parts. This technology is a game-changer for industries that demand high precision and intricate component designs, enabling extremely accurate machining of “problem” parts. In this post, we’ll explore the magic of wire EDM, showcasing its […]