When Necessity Sparks Reinvention

“Necessity is the mother of invention.” A phrase I’ve heard countless times and in 2014, I lived it. Just a year after launching Meron Medical, “necessity” drove an essential pivot in the direction of the company. That shift led us down a new road, becoming a critical player in the sophisticated world of high-end corewire grinding. But the journey down that road was far from easy.

A Pivotal Moment—And an Unexpected Turn

In 2011, M&S Centerless Grinding my family business and the foundation from which Meron Medical was born, solved a manufacturing challenge that had stumped our CMO competitors. We successfully produced a stainless-steel delivery cylinder for a Transcatheter Aortic Valve Replacement (TAVR) procedure. The project looked promising! After all it came from one of the 800-pound gorillas in the valve replacement sector.

Though M&S’ niche grinding capability was second to none, I had the urge to seize this opportunity. This potentially substantial project could start a company that would blossom into a contract manufacturer focused on challenging parts in the Interventional MedTech space. It was a good idea. It held water.

I leased space, hired people and bought equipment to support the TAVR project. We didn’t yet have a contract in-hand, but the Director of Global Outsourcing at our behemoth client called me directly to ensure that our newly formed Meron Medical, LLC was ready to step into our next chapter together with them.

Then, the project, very unfortunately, took a left-turn. Just like that, we were left standing at the altar. Ouch.

Chasing a Vision in Interventional MedTech

I could have called it quits and closed the doors of Meron Medical at that point. Rolled everything back into M&S Grinding, licked my wounds a little, and forged on. No chance, that option felt too easy. Especially since Meron Medical was named after my dad who had passed 10 years before. My father was a model of perseverance. It would be an insult to his memory to fold without giving this a go. Plus, I saw great potential in owning a MedTech CMO.

A Seamless Shift to Corewire Excellence

Instead, I dusted off a Royal Master Gen-X grinder and made some calls. Maybe guidewire/corewire grinding could provide enough revenue to keep this idea, and this company, alive. As it turned out, we took to it like a duck to water. Our crew pivoted seamlessly to corewire grinding by applying the decades of high-level grinding experience learned at the Mother Business. We attacked, and overcame, corewire grinds that had stumped some of the largest, and most capable, guidewire grinding companies in the industry. The new little entrant was good. We had a niche.

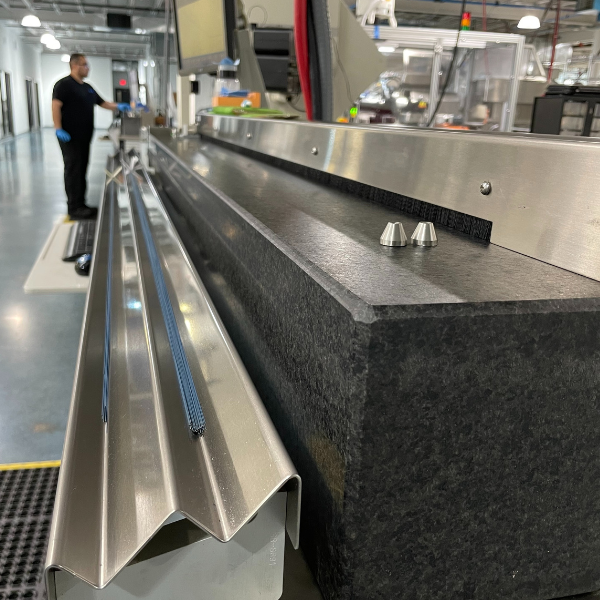

What Sets Us Apart in Corewire Grinding

Fast-forward more than 10 years and a merger later, and guidewire/corewire grinding has become a true Center of Excellence for KMM Group, Ltd. And it’s not the addition of many more grinding machines or the large high-tech space we moved into that makes us good at what we do. Anyone can buy machines and a building, it’s what you do with them that matters. Over the years we’ve stretched ourselves to develop the IP, through trial and error we’ve developed the expertise. That’s what sets a company apart from its rivals.

Success in this “imaginative space” is directly linked to having the right people with the right experience and immersing them in a culture that fosters values such as perseverance, innovation, and acting boldly and with conviction. This is what we bring every day, and this is why we smile when an engineer lays down a challenge by saying “I think I designed something that can’t be made.”

Interested in bringing your bold ideas to life? Reach out, we can help.