Machining

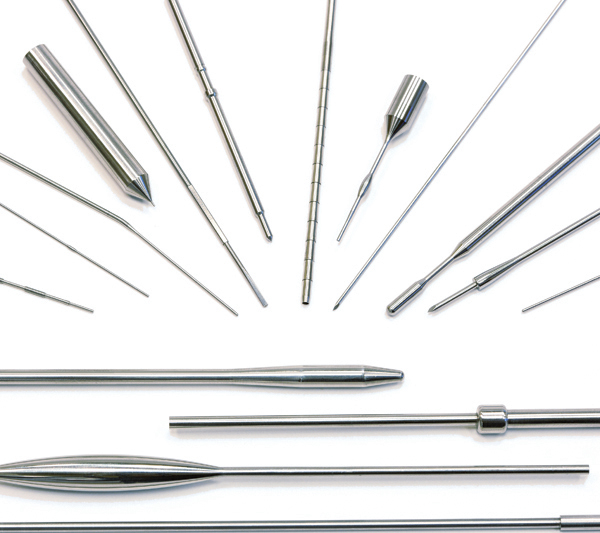

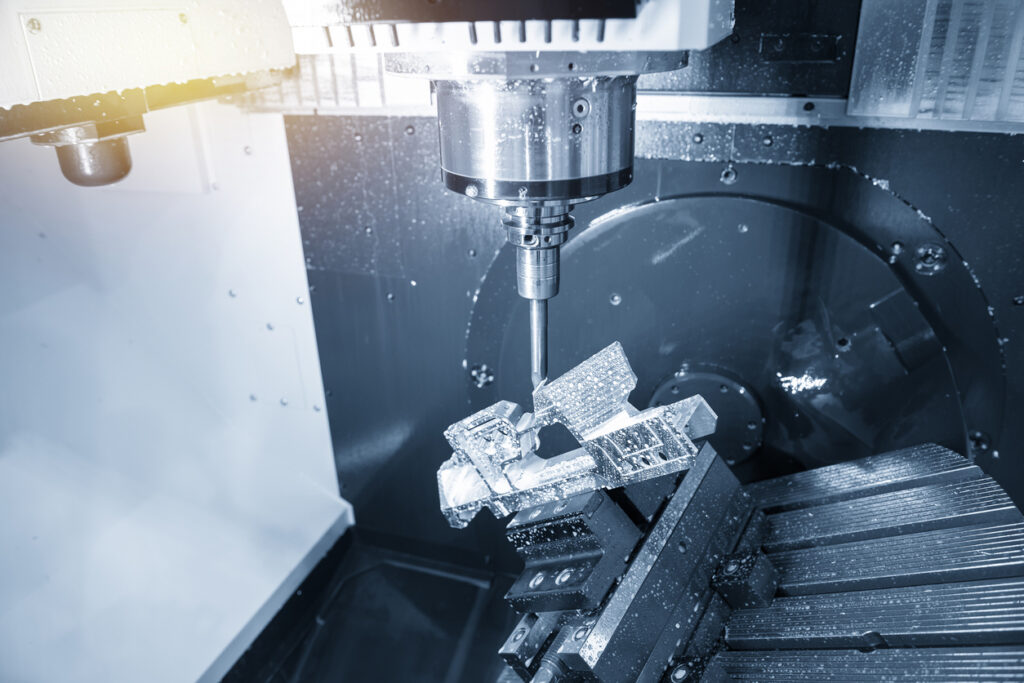

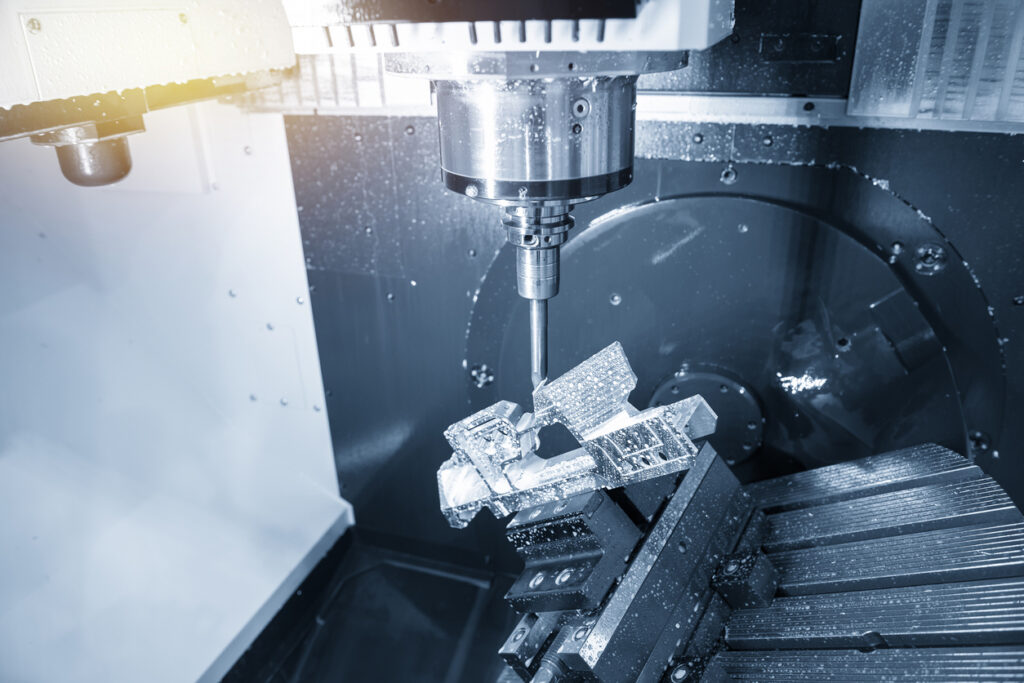

Ultra-Precision Machining (Milling)

Our ultra-precision vertical machining capabilities produce highly accurate results with tolerances as low as 2.5 microns. We offer 3-, 4-, and 5-axis milling and finishes to < 8 Ra to meet your most exacting standards. As specialists of medical and aircraft alloys, we have the tools and expertise to deliver precisely the solution for your manufacturing challenge.

Envelope up to 40” x 20” x 20”

3-, 4-, and 5-axis milling

Specialists in working with medical and aircraft alloys

Tolerances to .0001” (2.5 microns)

Finishes to < 8 Ra

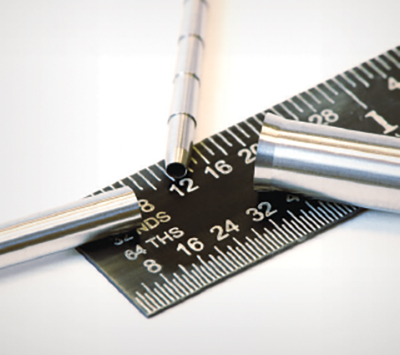

Wire EDM

Our wire electrical discharge machining (EDM) capabilities provide precise prototype or production solutions using any material your project requires, including any necessary certifications. With rapid turnaround service and ultra-precision near-zero tolerances, we blend talent, passion, and technology to boldly generate the results you need when you need them.

Wire EDM

Our wire electrical discharge machining (EDM) capabilities provide precise prototype or production solutions using any material your project requires, including any necessary certifications. With rapid turnaround service and ultra-precision near-zero tolerances, we blend talent, passion, and technology to boldly generate the results you need when you need them.

RAM EDM

Hex, Torx, Clover and other Socket Features for Surgical Devices and Implants

Fine Finish Performance to 4 RMS

0.0002” Tolerance Capability

Thin Wall/Deep Cavity applications

EDM Drilling

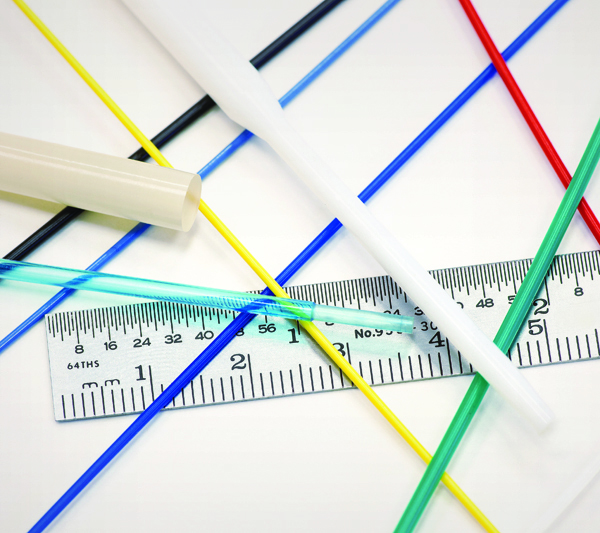

Swiss Screw Machining

Our 13-axis Swiss screw machining capabilities can produce high-precision components with tolerances as low as 5 microns. Ideal for close tolerances and complex parts, our Swiss department delivers exacting precision on low to high volume runs of 50 to 500,000 parts.

Up to 32mm through the spindle

Up to 13 axes

Tolerances to .0002” (5 microns)Specialists in working with medical and aircraft alloys

ow volume to high-production (50 to 500,000 pieces)

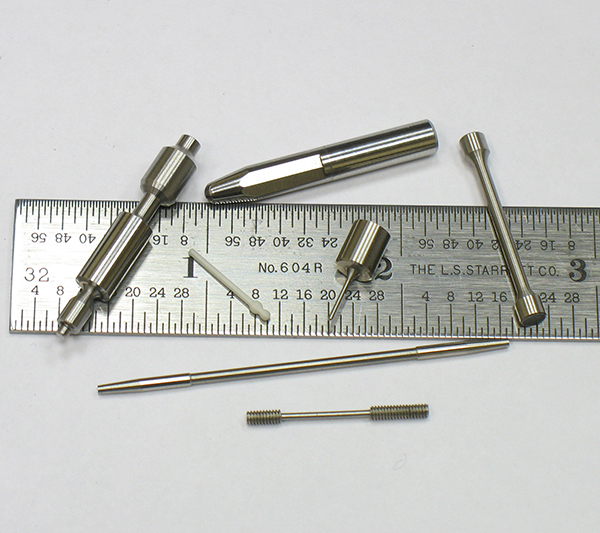

Micro-Machining

Our micro-machining capabilities blend the latest state-of-the-art technologies with advanced technician experience to deliver ultra-fine parts with near-zero tolerances. Fueled by our passion and commitment to excellence, we have the advanced skills and equipment to meet your most exacting standards.

Extremely small, intricate components

Features as small as .002”

Tolerances to microns

Possible in all manufacturing disciplines – Swiss, milling, EDM and grinding

Mill Turns

Our milling/turning capabilities combine state-of-the-art equipment and talented machine technicians to produce complex parts within near-perfect tolerances, giving us an edge in high-precision industries. Our deep dedication to excellence and vast experience with an extraordinary number of material types make us the leading supplier to tier-one aerospace companies around the globe.

3.15’’ bar through spindle and 17” between centers

11-axis capability

.0002” tolerances

8 Ra finishes

Experience with over 60 materials

Mill Turns

Our milling/turning capabilities combine state-of-the-art equipment and talented machine technicians to produce complex parts within near-perfect tolerances, giving us an edge in high-precision industries. Our deep dedication to excellence and vast experience with an extraordinary number of material types make us the leading supplier to tier-one aerospace companies around the globe.

3.15’’ bar through spindle and 17” between centers

11-axis capability

.0002” tolerances

8 Ra finishes

Experience with over 60 materials

Tooling / Toolmaking

The KVI division started as a high-end tool & die shop and has always remained connected to its roots. Boasting 45 years of engineering solutions to complex challenges, our dedicated toolroom and vast experience with tooling and fixturing gives us a leg up on our rivals, continually providing solutions where others see problems.

Industry Focus

We have worked within the medical, aerospace, defense, high-tech, and power generation industries for a combined 100 years helping to solve mission-critical manufacturing challenges. We are your trusted source for accurate and timely high-precision components.

Medical – Components for medical equipment and devices

Aerospace – Fighter jet parts, space exploration parts, intricate valve spool and actuators, test coupons

Defense – Firearm bolts and carriers

Robotics – Pinion gears and actuator bodies

High-tech – Motor shafts, air bearing spindles, race engine parts