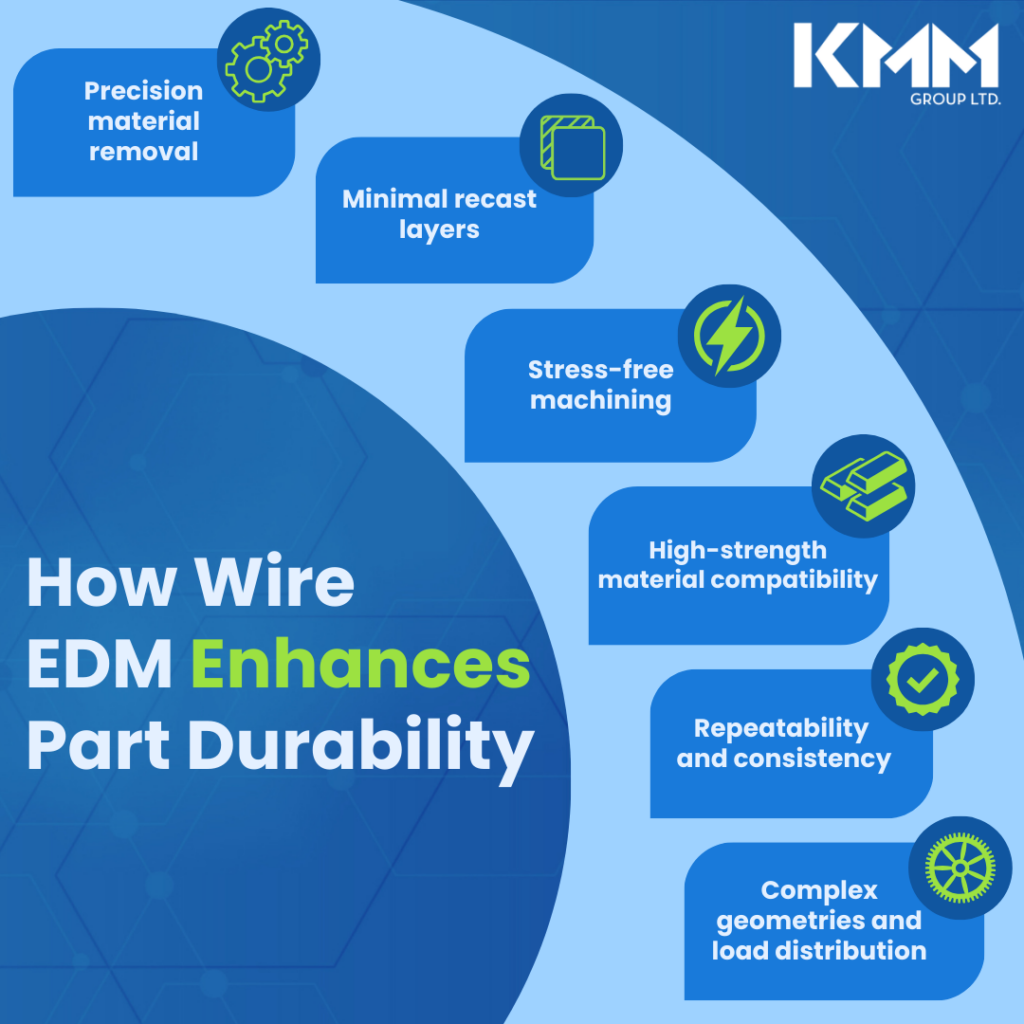

Building Tougher Components with Wire EDM

Producing strong and durable components is essential for the success and safety of critical missions and applications in fields like medtech, space exploration, and aerospace. When lives and investments are on the line, parts must be machined to endure the demands of a human body, the grueling conditions of space, or the high stress and […]

How to Design Die Components for Wire EDM: Timeless Insights from a KMM Forefather

Discover timeless Wire EDM design tips from KMM’s founder to enhance precision and repeatability in manufacturing.

Wire EDM Success: How Material Compatibility Makes A Difference

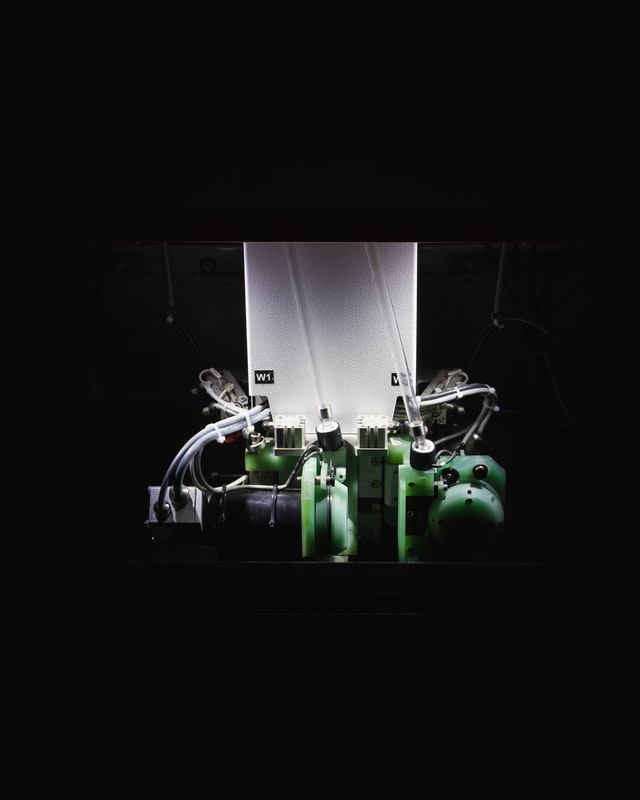

Wire EDM (electrical discharge machining) is a specialized manufacturing process offering exceptional precision, complex geometries, consistent quality, quick turnarounds, and cost-effectiveness. Its easy setup, efficient programming, and ability to stack parts significantly reduce cycle time. The process is highly repeatable and can run for extended periods without inducing stress on the materials. This technology is ideal […]

Complex Precision Parts Simplified: The Magic of Wire EDM

Wire EDM is an advanced precision manufacturing process that unlocks endless possibilities for creating intricate geometries and fine details in parts. This technology is a game-changer for industries that demand high precision and intricate component designs, enabling extremely accurate machining of “problem” parts. In this post, we’ll explore the magic of wire EDM, showcasing its […]

What is the Difference Between Wire and Ram EDM?

While the early concept of electrical discharge machining (EDM) dates back to the 18th century, modern EDM began in the 1960s with the emergence of the first wire electrode machines. Since then, EDM technologies have continually evolved to allow skilled craftspeople to machine precise and complex shapes that would otherwise be difficult to produce with […]