The manufacturing landscape is evolving fast. Designs once considered “too complex to machine” are now standard requests. As components get smaller and performance requirements grow tougher, traditional machining centers struggle to keep up. The smarter move? 13-axis Swiss screw machining, which delivers the accuracy, flexibility, and efficiency modern programs demand.

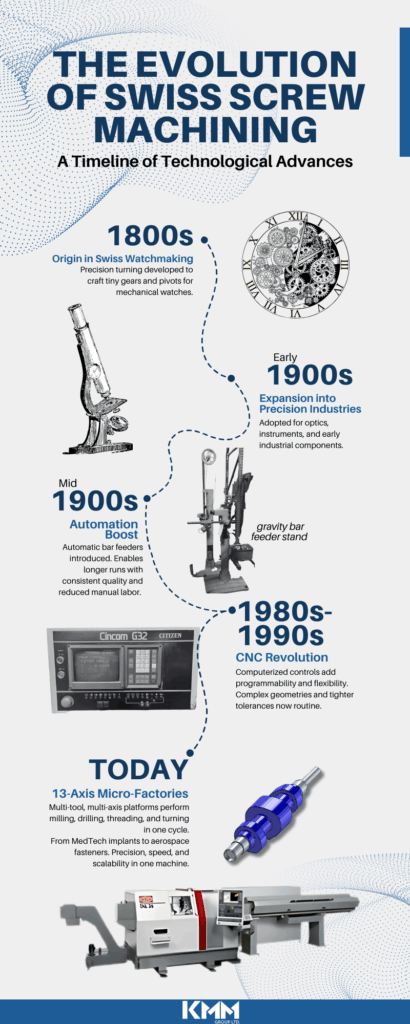

And this capability didn’t appear overnight. Swiss screw machining began in the 1800s, created to manufacture impossibly precise watch parts in Switzerland. Its genius was the guide bushing. This design stabilized long, slender parts and allowed watchmakers to achieve microscopic detail without deflection. Over the decades, this principle spread to other industries, evolving with CNC controls, more tooling stations, and expanded axes of motion.

The result? Today’s 13-axis platforms act like a micro-factory in one footprint. Milling, drilling, threading, and turning happen simultaneously, cutting lead time and scrap while raising confidence in every part. It’s a time-tested process, re-engineered for the challenges OEMs face today.

A Quick Look Back

Late 1800s: Invented in Switzerland to produce watch parts with extreme precision.

Early 1900s: Adopted for small, complex parts in other industries like instrumentation and optics.

Mid-20th century: Integration of automatic bar feeders increased productivity for longer runs.

1980s–1990s: CNC technology transformed Swiss machining, adding programmability and flexibility.

Today: Multi-axis platforms (up to 13 axes) perform milling, drilling, threading, and turning simultaneously, functioning as compact “micro-factories.”

Why 13-Axis Swiss Screw Machining Stands Out

1. Precision at the Micron Level

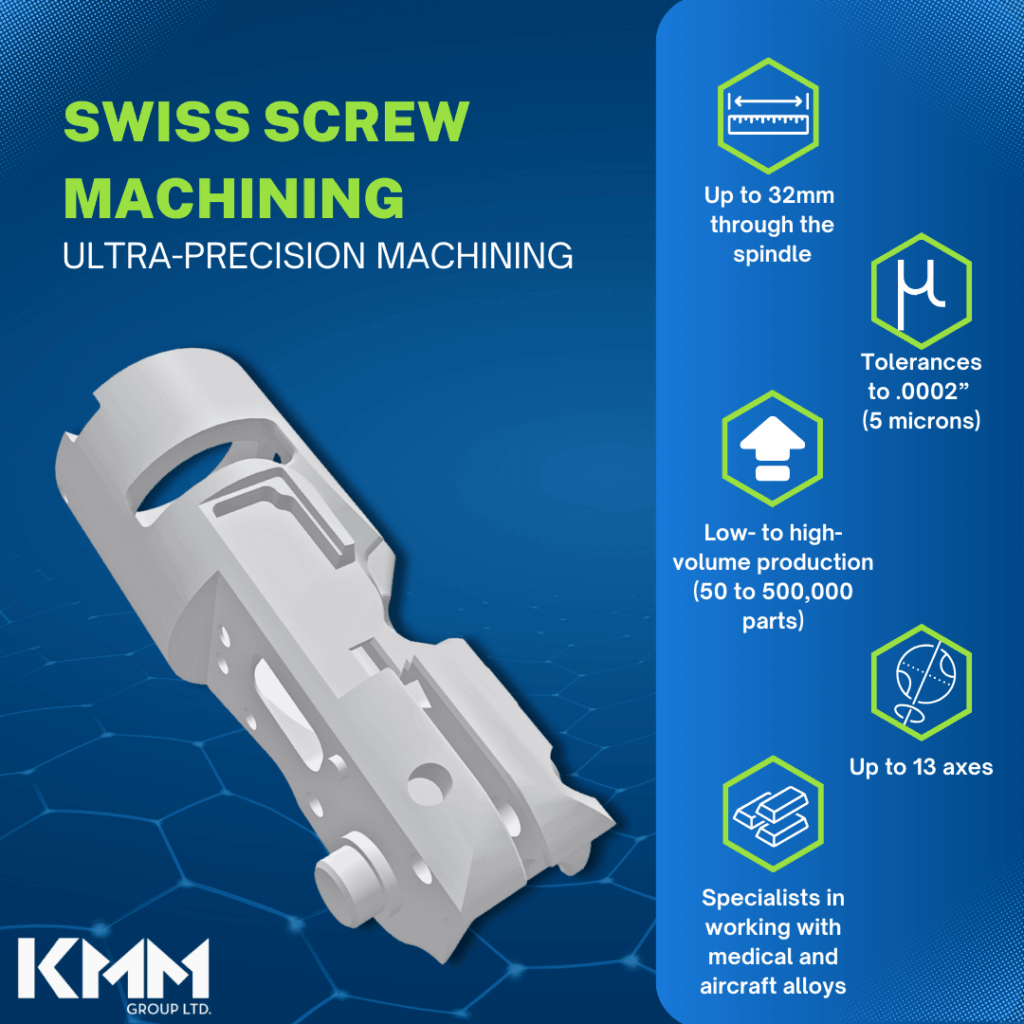

We’re talking tolerances down to 0.0002 inches (5 microns). This isn’t overkill—it’s essential when performance depends on flawless fit and function. From surgical implants to aerospace connectors, those tolerances can literally make or break the success of a component.

2. Miniaturization and Complex Geometries

Need a part with details finer than the lead in a pencil? These machines routinely produce features as small as 0.002 inches, making them ideal for micromachining applications where complexity and size converge.

3. Rigidity for Long, Slender Parts

Anyone who’s battled chatter, bending, or deflection during turning knows the frustration. The guide bushing and support systems in Swiss machines virtually eliminate these issues, holding even the thinnest workpieces steady while cutting.

4. Versatility Across Materials

From aluminum and brass to stainless steel, titanium, and specialty polymers, Swiss screw machining doesn’t shy away from variety. That flexibility means engineers can specify the best material for the job without worrying if the process can handle it.

5. Multi-Function Efficiency

Traditional machining often requires separate setups for milling, drilling, and turning. A 13-axis Swiss machine performs these operations simultaneously, cutting lead times dramatically and reducing or eliminating costly secondary processes.

6. Scalable for Any Production Run

Whether it’s a prototype batch of 50 parts or a full production run of 500,000, Swiss screw machining scales seamlessly. The repeatability and efficiency make it equally suitable for R&D projects and high-volume manufacturing.

The Machines Behind the Process

At its core, a 13-axis Swiss screw machine is a marvel of engineering. Multiple tool stations work together at once—milling, drilling, turning, and threading—in perfect synchronization. Advanced CNC controls allow engineers to program intricate toolpaths with unmatched accuracy, while automatic bar feeders keep production running smoothly with minimal downtime.

Instead of thinking of it as a “lathe,” think of it as a micro-factory in one footprint. It’s capable of replacing multiple machines and setups while delivering better consistency.

Applications That Demand This Level of Capability

Aerospace: guide pins, shafts, housings, fasteners, and precision fittings

Medical devices: bone screws, dental implants, infusion port stems,

Precision hardware: connectors, shanks, rods, and assemblies requiring both durability and repeatable accuracy

Bringing it all Together

Swiss screw machining delivers a lot on its own including tight tolerances, complex geometries, stable production for long, slender parts, and the ability to scale from prototype to high-volume runs. But in real-world OEM programs, that’s often just the beginning.

KMM Group’s Boutique CMO™ model blends Swiss machining with advanced grinding, R&D, and DFM support. So every project has the right mix of tools and expertise. We make more than parts. We have the processes and scalability you can rely on.