Inside the Mind of a Precision Grinding Estimator

Where Quality Starts in the Estimating Process

If you spend enough time staring at prints, certain things begin to jump out at you.

I don’t mean the obvious stuff like dimensions, tolerances, or surface-finish callouts. I mean the things underneath. The things customers usually never see, and the things KMM precision grinding estimator Joshua Brodbeck didn’t see himself until he’d spent years on the shop floor before ever touching a quote.

He never set out to become a precision grinding estimator. For eight years, Josh ran grinding machines. He saw how materials react when stress releases, how a tenth of a thousandth behaves differently depending on length or diameter, and how a part that looks easy on paper can turn stubborn in the real world. Then one day, back when KMM CEO John Shegda was running M&S Centerless Grinding, he told Josh that his attention to detail made him a natural fit for estimating. They tried a half-day split: grinding in the morning, estimating in the afternoon. Two months later, John walked in and said, essentially, “You’re done on the floor. I can’t be doing quotes at one in the morning anymore.” Josh never went back to the machines.

And nineteen years into his career, that decision is one of the reasons our quality starts where it does.

The Part That Looked Easy Until It Wasn’t

Why Experience Matters More Than the Print

At first glance, a trocar tip seemed straightforward. On paper, it looked like the kind of job KMM grinding technicians can do with their eyes closed. Straightforward geometry. Nothing that raised a flag right away.

But when the job hit the floor, trouble appeared immediately. Every attempt came back with a cosmetic flaw: a hairline scratch, a tiny dig, a faint swirl that only showed up when the light hit it the wrong way. “Their expectation of the print wasn’t our interpretation of the print,” Josh said. “And that hidden expectation changed everything.”

The fix turned out to be a polishing and deburring step no one had planned for.

That job taught him a truth most designers and buyers never see: estimates aren’t math problems. They are early warnings, small bets, and educated guesses layered with nearly twenty years of accumulated experience.

The job is solid now, but that early surprise reminded Josh that a quote is never just a quote. It’s the first safeguard in protecting quality.

Learning to See Problems Before They Happen

How Precision Grinding Estimating Reduces Risk

Most of us never think about what a tenth means.

For Josh, a tenth is the difference between success and a pile of scrap.

When Josh is estimating, he’s visualizing:

- What happens when tolerance drops under a tenth

- Whether the bar ends will naturally fall a couple tenths

- When stress will release and “wig out” into an S-shape

- How a soft material will fight you for size

- Whether thin-wall tubing will stay round or quietly betray you

“Early on, I thought some tolerances were nearly impossible,” said Josh. “Now, with context, they’re just numbers. There are two numbers, and if we can aim between the numbers, we’re making a good part.”

The trick is that every variable changes the story. That’s why context and experience matter for a high-quality estimate.

What Experience Teaches That CAD Never Will

Real-World Behavior vs. Idealized Models

Josh translates the realities of grinding into plain language, shaped by years of watching real parts behave on real machines.

Take thin-wall tubing.

After years of grinding catheter tubing, he knows the wall-to-diameter ratio where parts behave like willing partners, and the ratio where they turn mischievous, flexing under the wheel and drifting out of round. “Under fifty-to-one, we know it’s going to behave,” he said. “Beyond that, you add passes, slow things down, and give the guys time to do it right.”

Or corner radii.

He once debated an engineer who insisted a five-tenth radius was achievable because “the CAD model said it could be done.”

Josh explained that a grinding wheel isn’t an idea, it’s made of actual grains of abrasive. The tightest radius is the size of the grain itself. Physics doesn’t bend for software.

That’s where the shift happens.

Not in what’s toleranced, but in what’s real.

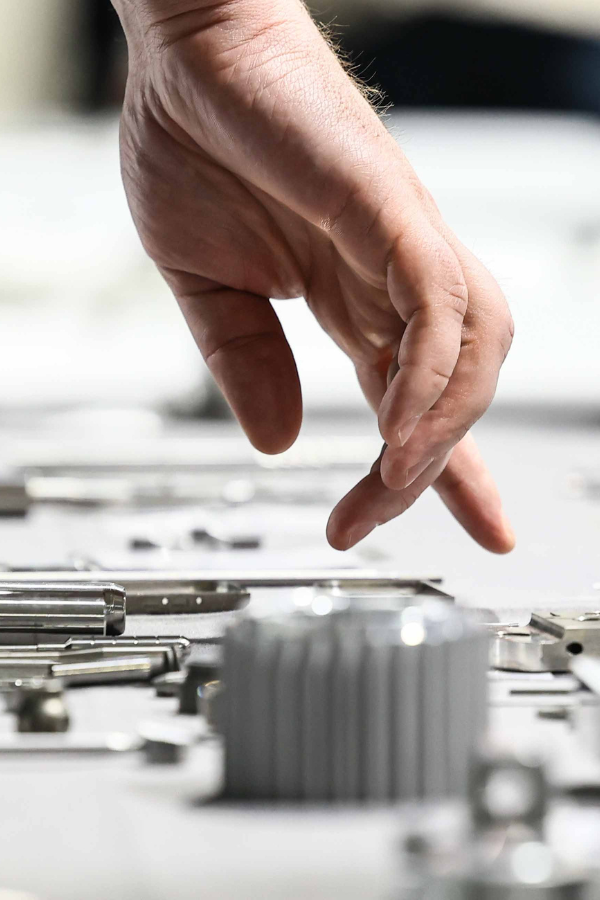

The Estimator Standing at the Machine

How Production Feedback Shapes Better Estimates

Imagine standing next to a machine while a river of small parts flows past you. 3,500 inches of material every hour, each pass narrowing the window until the part is dialed in. When everything is warm, stable, repeating, the machine enters a kind of rhythm.

And in that moment, Josh knows whether his estimate was right.

If the setup operator has the time they need.

If the passes land where they should.

If the part behaves the way the print suggested it might.

That’s where quality begins. It begins with a quiet moment of prediction weeks earlier, staring at a drawing.

Quality Isn’t an Outcome. It’s a Beginning.

Why Accurate Estimating Protects the Entire Workflow

Many people see estimating as step one.

But it’s actually step zero.

Quality starts in the invisible space where someone studies a print and imagines all the ways it could go wrong and then builds enough time, enough care, and enough passes into the job so the shop floor never has to experience those wrong turns.

As Josh put it, “It’s just a matter of taking your time within reason, to just evaluate all the factors that are going into it and then reducing risk and providing the most accurate quote possible.”

That’s the real secret of estimating.

It isn’t about numbers.

It’s about protecting the work long before the work begins.