How an O-Chem Lab in 1986 Changed My Life

I bet that’s not something you saw coming from a life-long manufacturing guy.

I graduated from Penn State in 1987. I was planning for a future as a doctor. After nearly 40 years in manufacturing, I think it’s safe to say that ship has sailed. But here’s the thing: those four years that I spent pounding the books and pulling all-nighters at my alma mater weren’t wasted. In fact, one class in particular gave me a blueprint for how we solve problems at KMM every day.

In my junior year I had an Organic Chemistry lab. The lab spanned the entire year. First semester, we were taught a series of lab techniques to identify the characteristics of different compounds. Second semester, we were each given an unknown compound and told to use those techniques to break it down and determine the components of its composition.

So, how does this apply at all to manufacturing?

The Process That Stuck

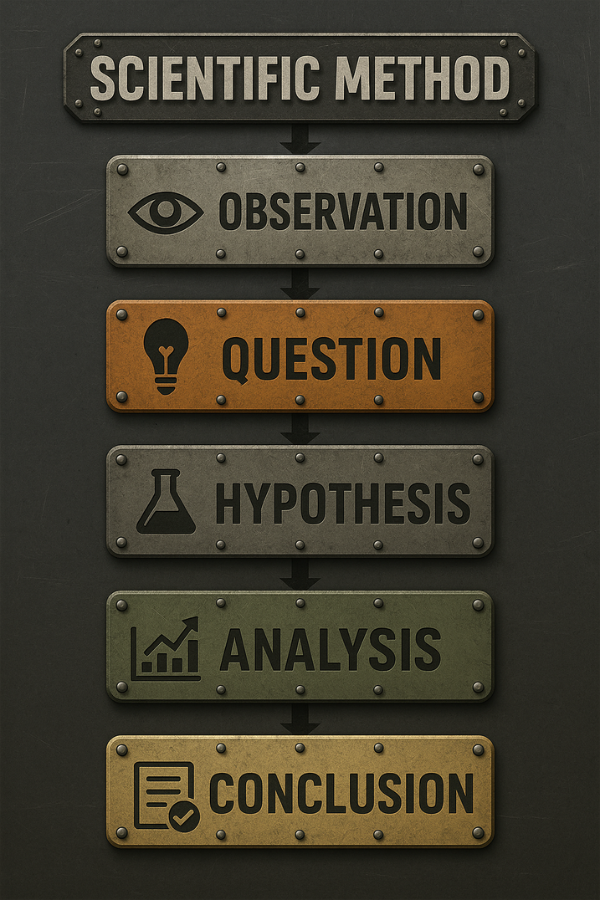

Well first, let me allay your fears – I earned an ‘A’ in the class (maybe I would have been an okay doctor). Not by chance, but because I used the scientific method of careful observation and process. When I tested a variable, I recorded everything. What changed, what didn’t, what I saw, what time it was. I even noted the cleanliness of the lab equipment, and the atmospheric conditions (warm, cold, rainy). After numerous cycles of this process, I read back through the data, looking for patterns. One test didn’t mean much. But examined holistically, the pieces told a story.

It was like that game we all played as kids: getting warmer….getting warmer…oops getting colder…..ah! warmer….warmer….hot!!

I couldn’t tell you now what compound I was handed, or the chemical techniques that I learned in the class. But the process by which I solved the problem stuck with me. In fact, aside from a deep love for college football, this O-Chem lab might have been the single most impactful experience in my four years at PSU.

If It Can’t Be Taught, It Can’t Scale

Today, we teach this methodology to our team. It’s a requirement not because it’s efficient, but because the goal of any problem solver should be more than just good parts. It should be to develop a repeatable and transferable process that can scale to the requirements of a program. Most importantly, it shouldn’t require the person that created the process to run it effectively.

Too often, a difficult project is handed to “the old hand” because they know when and where to “lean on the machine” to get the parts to run. This may work for one project, but it’s not science. It’s what’s called Black Art, and it should have no place in modern manufacturing. Sure, there’s pride in being the one everyone relies on for their “magic” results. But real problem solving isn’t magic. It’s a process that draws deeply on experience and requires copious amounts of perseverance to dutifully and methodically test one variable at a time, record what happens and look for patterns.

This mindset must be baked into the DNA of the company. For us, it’s observing everything and taking nothing for granted. It often seems to be things that you’re ‘sure’ won’t work that play an important role in the solution. And if you stick with the process diligently, you’ll start to hear it: The tumblers clicking into place. Unlocking the Science of Manufacturing.