Supply Chain Resilience: From Reactive to Proactive with 3 Strategies

If the last few years have taught us anything, supply chains are more vulnerable than ever to fluctuating market demands, unforeseen disruptions, and the relentless pace of technological advancement. To overcome these hurdles and cultivate a smooth, efficient, and cost-effective supply chain, it’s essential to embrace flexibility, cost-efficiency, and streamlined operations. In this post, we’ll […]

How to Outsmart the Challenges of Exotic Metals & Alloys in Manufacturing

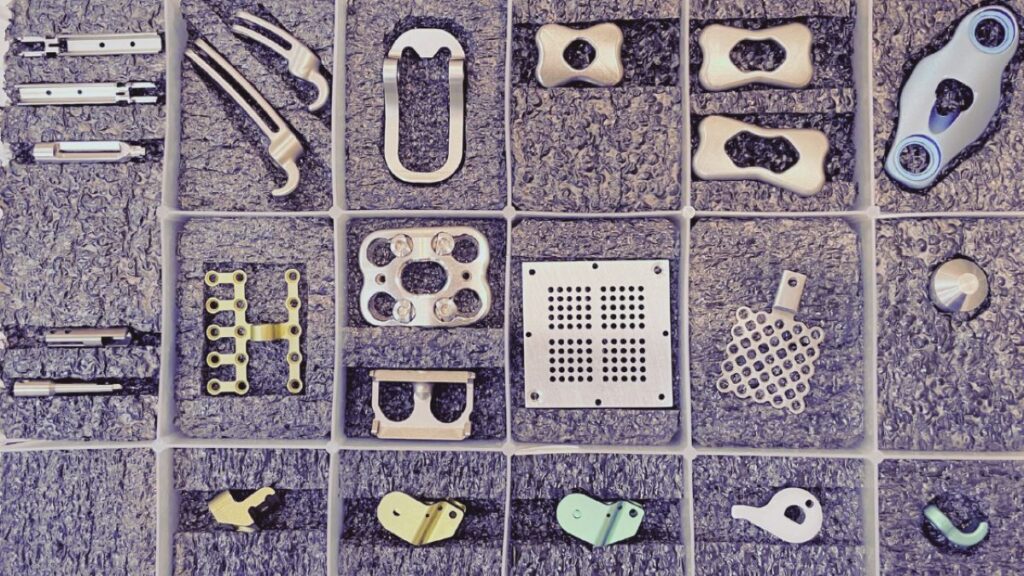

Mission-critical industries like aerospace and medtech are essential to our daily lives and often rely on components made of remarkable yet difficult-to-manipulate materials. These materials can withstand the incredible G force in flight and allow for safe placement and optimal functionality inside the human body. For example, nitinol is a member of a group of […]

5 Cost-Effective Space Manufacturing Strategies Worth Exploring

Space exploration has always fascinated humanity, from the early days of satellite launches to the latest crewed missions to the International Space Station. However, the cost of building and launching equipment into space remains one of the biggest challenges in the field. As we look towards the future, we predict that the economics of space […]

FDA Registration: MedTech Edition

The U.S. Food and Drug Administration (FDA) plays a critical role in ensuring the safety and efficacy of medical devices. Medtech manufacturers must comply with FDA regulations. In this article, we will discuss the registration process for medtech manufacturing, its importance, and how to verify a company’s registration status. Understanding the Registration Process The registration […]

ITAR Registration: A Critical Necessity for Aerospace and Defense Manufacturers

International Traffic in Arms Regulations (ITAR) is a set of regulations that govern the export, import, and brokering of defense-related articles, services, and technologies in the United States. ITAR registration is essential for aerospace and defense manufacturers that deal with sensitive materials and technologies. Let’s explore the concept of ITAR registration, its significance, and the […]

5 Proven Benefits of In-House Custom Tooling & Fixtures

Many mission-critical components require custom tooling or fixtures, such as dies, jigs, and casting molds, to ensure they’re as precise as possible. However, some manufacturers cannot produce custom tooling and fixtures in-house. In this post, we’ll explain why in-house tooling and fixturing are essential for achieving the precision and cost-effectiveness you require. Whether using vertical […]

5 Cutting-Edge Techniques For Safe And Effective Orthopedic Medical Devices

Orthopedic medical devices are vital for improving the quality of life for individuals suffering from bone or joint-related injuries or conditions. These increasingly complex devices, which include artificial joints, screws, and plates, must be manufactured with extreme precision to ensure their safety and effectiveness. To achieve an exceptionally high level of precision, we deploy a […]

An Engineer’s Guide to Resolving Manufacturing Feasibility Uncertainties

Unchecked manufacturing feasibility uncertainties can throw a mission-critical manufacturing project off course, increasing the risks of project delays, unexpected costs, and late time to market. However, when your engineering design process includes protocols intended to reduce uncertainties before proceeding to full production, your machining and grinding projects have a much greater chance of success. This […]

The Importance of Rapid Prototyping for Expediting Your Time to Market

No matter which industry you’re in, from aerospace and medtech to high-tech and space exploration, the pressure to bring your innovation to market the fastest is red hot. Entering a new market time- and cost-efficiently often puts you at a competitive advantage and helps seed your position as an industry leader, making speed a chief […]

How to Prevent Unexpected Manufacturing R&D Costs

The research and development (R&D) process for manufacturing mission-critical aerospace, medtech, defense, high-tech, or space exploration components can be costlier than expected without the right resources and strategy. This post will outline several ways to prevent expensive delays and redesigns in the R&D phase to keep your project on track and within budget, including: Engage […]