KMM’s Quest for Perfection: A Deep Dive into State-of-the-Art Quality Machines

What differentiates a leader from the rest in the competitive precision manufacturing arena? In part, it’s a firm resolve to invest in cutting-edge technology for absolute perfection. In this article, we’ll explore the advanced quality equipment that positions us at the forefront of the industry. We’ll touch on the functionalities, capabilities, and unique advantages of […]

Setting the Bar Higher: Our Journey to Quality Innovation

In 2020, KVI, M&S Grinding, and Meron Medical united to form KMM Group. This merger symbolized more than a business decision—it embodied a shared vision. Stemming from this union was an organization-wide mission to seamlessly integrate all three business units, both operationally and physically. By the spring of 2021, driven by our vision, we took […]

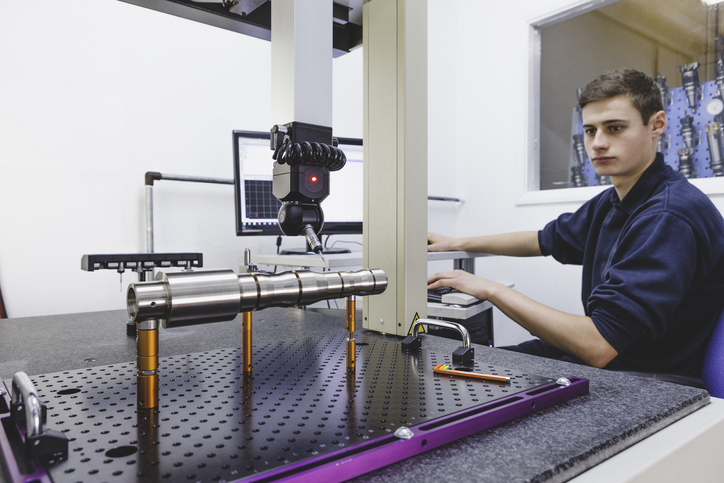

5 Types of Metrology Inspection Equipment for Maximum Accuracy & Precision

As we in the manufacturing sphere all know, accuracy describes how closely a part conforms to a tolerance within a specified dimensional range. The closer a part conforms to your standards, the better your results. Ultra-precision component manufacturing levels up the notion of accuracy with the ability to hold diameter size, roundness, and cylindricity to […]

How 3D Printing Technology Enhances Our Guidewire Inspection & Packaging Processes

Harrison (Harry) Lo is a bright mechanical engineer co-op from Drexel University’s School of Engineering. He joined the Meron Medical team for a summer internship to balance classroom theory with practical, hands-on experience. With interest in engineering process analysis and quality assurance, Harry dove into various aspects of our medical component manufacturing while continually exploring […]