Wire EDM (electrical discharge machining) is a specialized manufacturing process offering exceptional precision, complex geometries, consistent quality, quick turnarounds, and cost-effectiveness. Its easy setup, efficient programming, and ability to stack parts significantly reduce cycle time. The process is highly repeatable and can run for extended periods without inducing stress on the materials. This technology is ideal when conventional machining methods fail, such as when working with materials like Trabecular Metal (TM), where traditional machining would smear the material and fill in the voids, greatly diminishing its benefit.

But here’s the catch: For wire EDM to work its magic, the material must be electrically conductive. This blog post will dig into the science behind this specific material requirement and showcase examples of electrically conductive materials that can be processed.

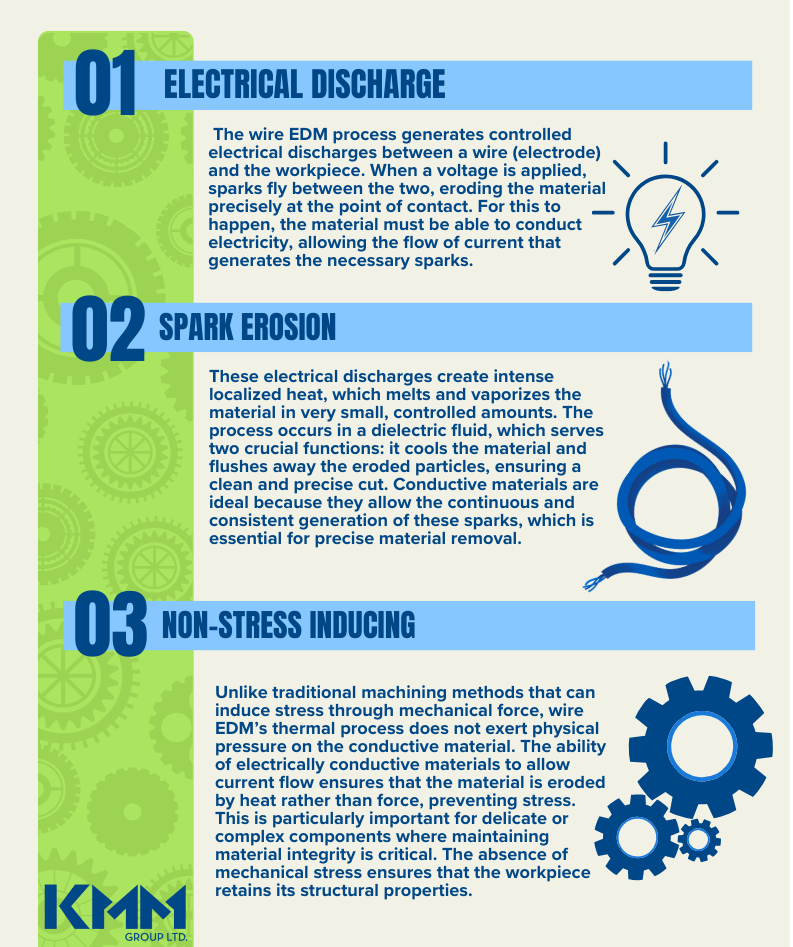

Wire EDM Only Works with Electrically Conductive Materials: Here’s Why Wire EDM relies on a fundamental principle: the processed material must be electrically conductive. This requirement stems from the nature of the process, which uses electrical discharges (sparks) to erode the material. Here’s the science behind why electrically conductive materials are essential to wire EDM processing:

Exploring Wire EDM Compatible Materials

Electrically conductive wire EDM-compatible materials range from common metals to those that are notoriously difficult to machine using traditional methods, such as Hastelloy and Inconel. These materials are often used in high-stress, high-temperature environments due to their durability and performance. Here are more types of electrically conductive materials compatible with wire EDM:

Non-conductive materials like plastics and ceramics cannot be processed with wire EDM because they lack the required electrical conductivity. Without this property, the electrical discharges have no effect, making wire EDM ineffective for non-conductive materials.

Is Wire EDM Right for Your Project?

Deciding whether wire EDM is suitable for your project largely depends on the materials you are working with and the precision required. If your project involves electrically conductive materials and demands intricate cuts or complex geometries, including micro-sized parts, wire EDM is likely an excellent choice. Additionally, wire EDM offers a precise, stress-free alternative if your materials are challenging to machine using conventional methods.

When considering whether wire EDM is right for your project, ask yourself these questions:

- Does your project involve electrically conductive materials?

- Does it demand intricate cuts or complex geometries?

- Does it use materials that are hard to machine with traditional methods?

If you answered yes, wire EDM is likely suitable for your project. This advanced machining process provides the precision, reliability, and efficiency to handle the most challenging manufacturing requirements as long as the material compatibility requirements are met.

Your Wire EDM Experts

We are wire EDM experts with extensive experience handling various materials, including those that are delicate or difficult to machine. Our commitment to precision and quality, with advanced technology and specialized procedures, makes us a trusted partner in achieving your manufacturing goals. Additionally, we follow special standard operating procedures (SOPs) for high-value materials related to storage and control, ensuring your materials are handled with extra care and integrity throughout the manufacturing process. Contact us to learn how our wire EDM services can benefit your next project.