Unveiled: Top Precision Manufacturing Techniques for Space Components – Part Two

As we covered in Part 1 of this two-part blog series, game-changing precision space manufacturing techniques like 5-axis milling, mill-turn, and cylindrical grinding have the potential to revolutionize the way we discover and understand the universe. These innovative techniques empower engineers and project managers to overcome seemingly insurmountable challenges that can derail space component manufacturing […]

Unveiled: Top Precision Manufacturing Techniques for Space Components – Part One

Game-changing precision manufacturing techniques in the space component industry are transforming how we explore the cosmos, potentially revolutionizing the field. These cutting-edge disciplines enable engineers and project managers to tackle challenges that often throw space component manufacturing projects off course or halt them altogether. The challenges the latest manufacturing techniques address are no small feat, […]

Elevating Precision: Critical Aerospace Components Redefined

The aerospace industry demands high-precision and high-quality components to ensure the safety and reliability of an aircraft. The accuracy of these components is crucial, as even the slightest errors can have catastrophic consequences. This is where precision machining and grinding can play a significant role in ensuring the accuracy and precision of critical aerospace components. […]

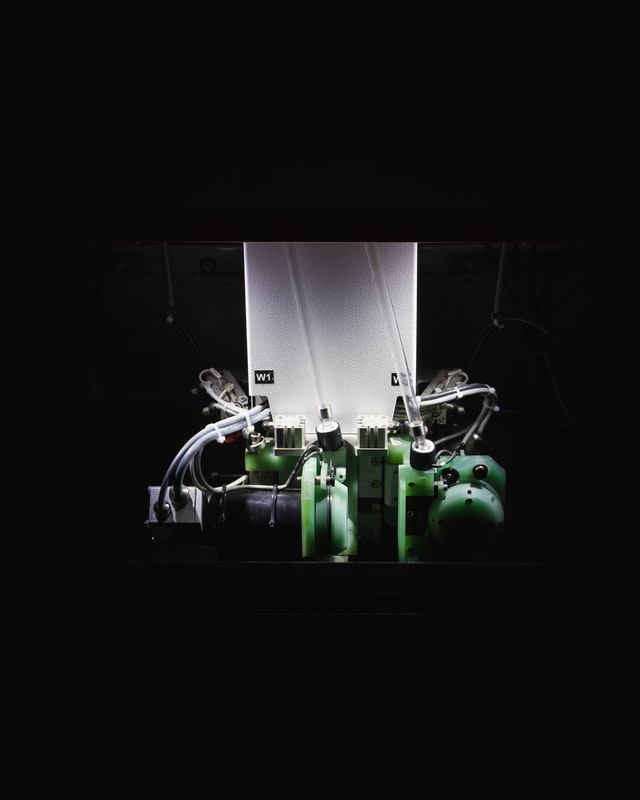

The Fundamentals of Achieving Super Thin Wall Thicknesses on Tiny Parts

Many component manufacturers deploy a CNC centerless technique when tasked with grinding tiny parts with super thin wall thicknesses. However, they can inadvertently crush them without the right grinding approach, triggering catastrophic results that drive up costs and timelines. So, the question becomes: How can super thin walls be achieved without compromising tiny parts? To […]

What is the Difference Between Wire and Ram EDM?

While the early concept of electrical discharge machining (EDM) dates back to the 18th century, modern EDM began in the 1960s with the emergence of the first wire electrode machines. Since then, EDM technologies have continually evolved to allow skilled craftspeople to machine precise and complex shapes that would otherwise be difficult to produce with […]

Is Your Defense Part Material Too Difficult to Manufacture?

Tight tolerances, thin walls, complex configurations, and visibly perfect finishes are among the chief defense manufacturing challenges. Still, nothing can ground a project liftoff faster than a difficult-to-manufacture part material. While straightforward materials like aluminum and stainless steel generally pose few complications, dozens of other exotic alloys can create significant obstacles on the production floor, […]

The Antidote to the Problem of Manufacturing Tiny Defense Parts

As defense components become smaller and more intricate, manufacturing challenges are on the rise. Without an effective production strategy, complex assembly configurations can trigger project delays and increased costs with a cascading effect downstream. If your tiny parts are causing big problems on the production floor, we’d like to introduce you to the antidote that […]

How 5-Axis CNC Machining Can Produce More Powerful Race Engines

When 23-year-old rookie Austin Cindric ran a thrilling race to win the 2022 Daytona 500 in a wild finish, he debuted the new, highly anticipated NASCAR Next Gen race car. While the engine features the same pushrod V8 engines as outgoing NASCAR cars, one critical aspect changed: power. After a chorus of calls for more […]

Leading the Way With EDM

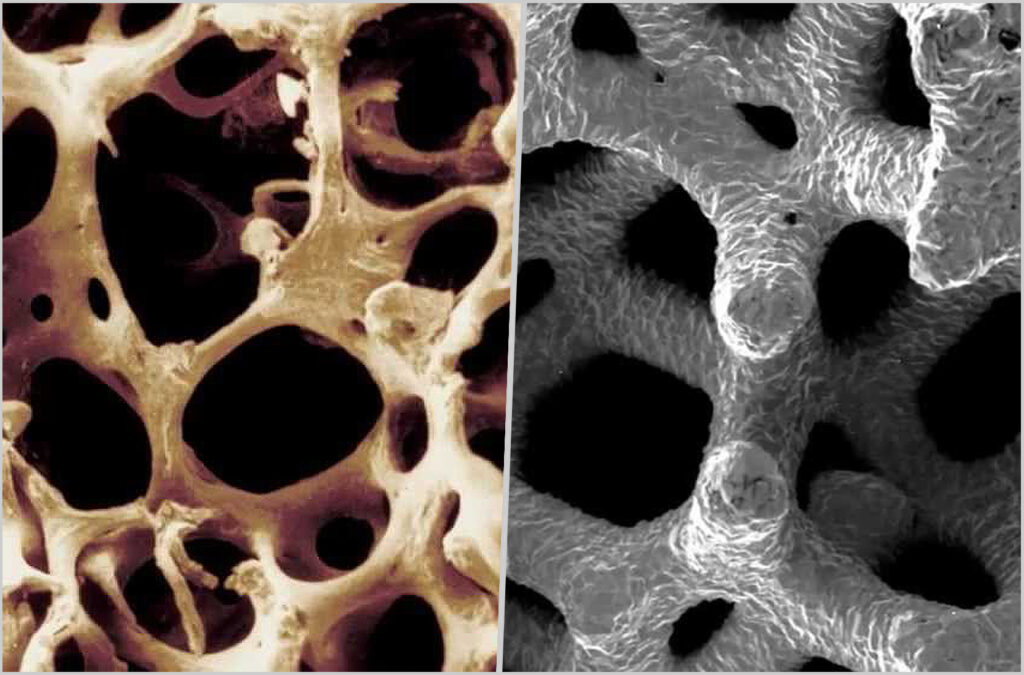

Have you ever worked with biomedical materials, in particular Trabecular Metal? Do you know what Trabecular Metal (TM) is? In the picture above, the TM is on the right, and a picture of the structure of bone is on the left. The, obviously, similar structures of the two, fosters the ability of the bone to […]