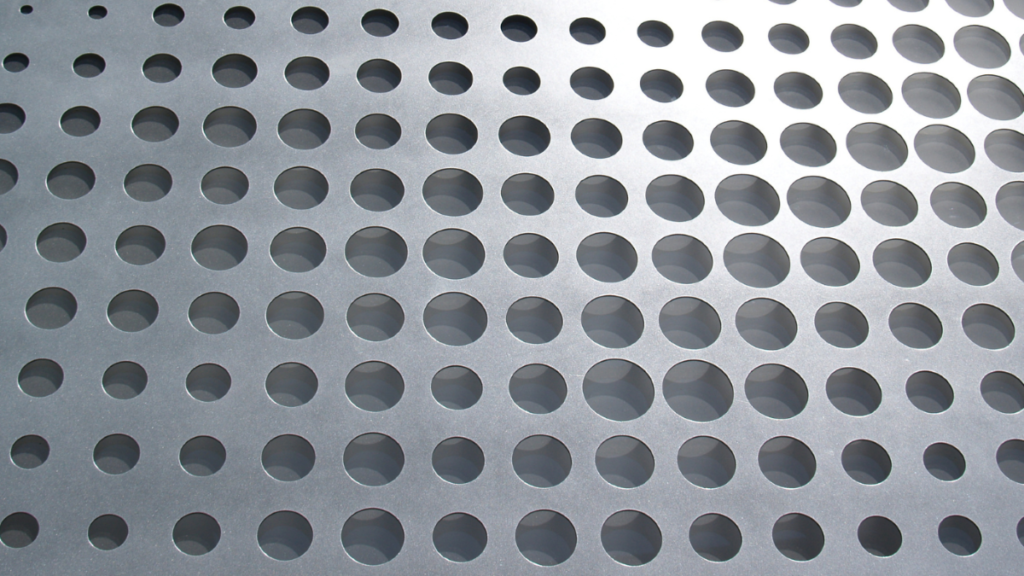

Wire EDM Success: How Material Compatibility Makes A Difference

Wire EDM (electrical discharge machining) is a specialized manufacturing process offering exceptional precision, complex geometries, consistent quality, quick turnarounds, and cost-effectiveness. Its easy setup, efficient programming, and ability to stack parts significantly reduce cycle time. The process is highly repeatable and can run for extended periods without inducing stress on the materials. This technology is ideal […]

Employee Spotlight: Wire EDM Specialist & Engineer Dan Costello

The dedication of our team makes KMM’s remarkable achievements possible. Through our Employee Spotlight series, we shine a light on the individuals who work tirelessly behind the scenes, significantly contributing to our success and the manufacturing industry overall. Today, we are featuring Dan Costello, who joined KMM in October 2002. With over 22 years of […]

5 Proven Benefits of In-House Custom Tooling & Fixtures

Many mission-critical components require custom tooling or fixtures, such as dies, jigs, and casting molds, to ensure they’re as precise as possible. However, some manufacturers cannot produce custom tooling and fixtures in-house. In this post, we’ll explain why in-house tooling and fixturing are essential for achieving the precision and cost-effectiveness you require. Whether using vertical […]

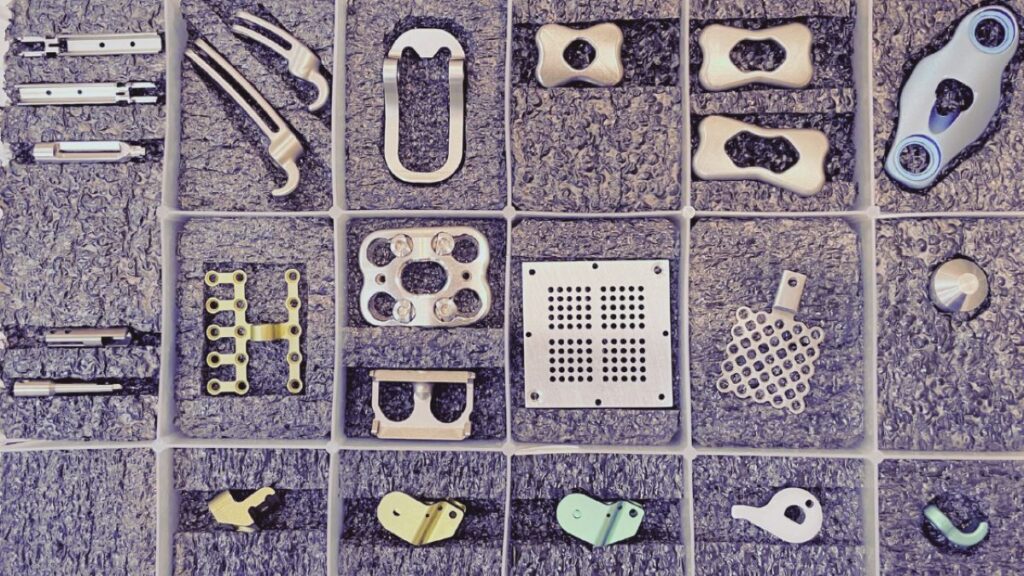

5 Cutting-Edge Techniques For Safe And Effective Orthopedic Medical Devices

Orthopedic medical devices are vital for improving the quality of life for individuals suffering from bone or joint-related injuries or conditions. These increasingly complex devices, which include artificial joints, screws, and plates, must be manufactured with extreme precision to ensure their safety and effectiveness. To achieve an exceptionally high level of precision, we deploy a […]

How We’re Rising to Meet the Future of Aerospace Component Manufacturing

Aerospace manufacturing flourished from 2004 to 2018 with continuous production rates and new program introductions. Then, the 2019 Boeing 737 Max grounding and the 2020 global pandemic emergence socked a one-two punch to the then-thriving industry, forcing a historic 70% drop in passenger demand between 2019 to 2020, the largest-ever year-over-year dip. Having endured […]

5 Aerospace Component Manufacturing Challenges – and How to Solve Them

The aerospace component manufacturing process can present obstacles that delay progress and increase costs. In this article, we’ll cover the five of the most common challenges and outline helpful solutions to help you overcome them: Tight tolerancing R&D uncertainties Difficult materials Complex designs Missing tooling/drawings Continue reading to learn more about solving these common […]