Guidewire grinding is a specialized niche within the medtech contract manufacturing organization (CMO) space, with capabilities varying significantly among providers. Choosing the right CMO is crucial for your medical device’s quality, efficacy, and safety. This decision is particularly important given the distinct strengths of larger-volume CMOs compared to those specializing in more intricate, lower-volume grinding. This blog post outlines five key factors to consider when selecting a guidewire grinding service, offering insights to help you choose a provider that best meets your specific needs and project complexities.

1. Precision and Customization

Many CMOs prioritize high-volume applications that feature less complex grind geometries, catering to common procedures in central vascular access, simple cardiovascular interventions, and urinary system treatments. These projects, often reaching production volumes in the millions, demand a provider with substantial surge capacity and a high level of automation due to their cost-competitive nature. In this segment, larger guidewire and corewire vendors excel, leveraging their scale to meet aggressive price points and production demands.

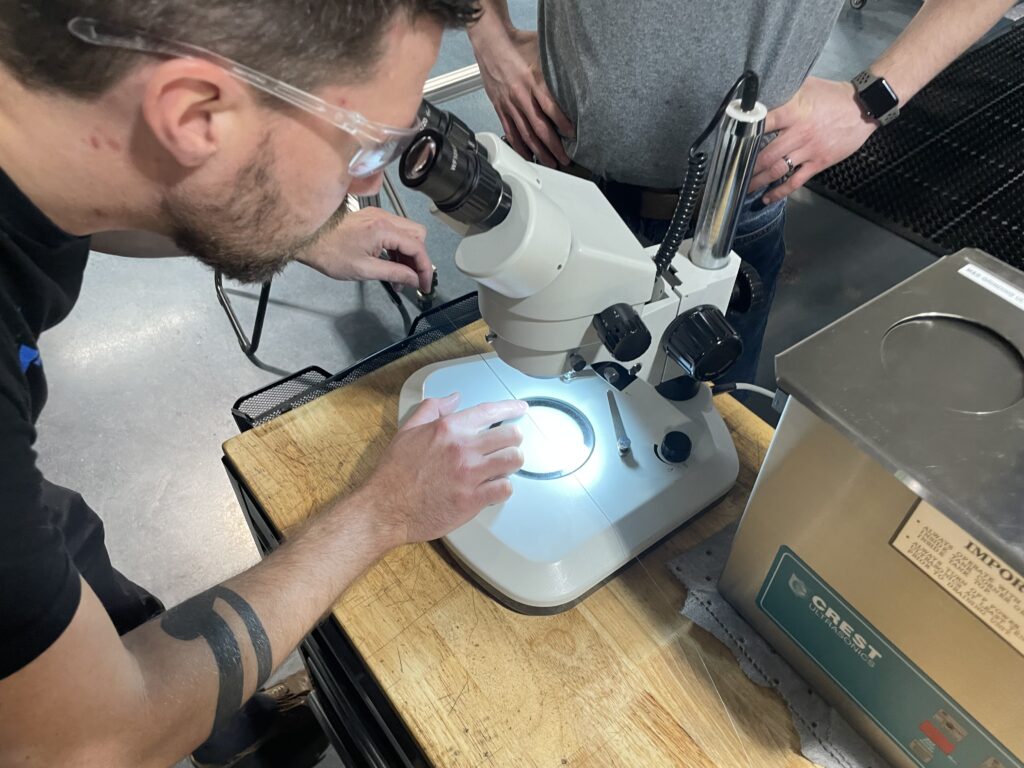

Conversely, another market segment focuses on more intricate guidewire and corewire grinding applications, such as those used in neurovascular or peripheral vascular procedures. These applications typically require extremely fine diameters, intricate steps, blivits, and extended grind lengths. Although annual volumes for these complex projects might still reach hundreds of thousands, individual orders usually do not exceed 50,000 units. The heightened complexity of these projects makes them challenging to automate, necessitating ongoing human oversight to maintain precision and adherence to specifications. With their hands-on approach and consistent shop floor presence, mid-sized CMOs are often better suited for these sophisticated projects, ensuring continuous production flow and consistent quality.

2. Quality Focus

When evaluating guidewire and corewire grinding CMOs, a critical factor is the extent and sophistication of quality control mechanisms implemented on the production floor. The distinction between CMOs prioritizing simpler, high-volume projects and those specializing in more complex, lower-volume tasks extends into this area. In high-volume productions, where quality processes are more standardized and stable, the reliance on extensive quality control infrastructure is reduced. These service providers benefit from established routines that ensure consistency, minimizing the necessity for constant, high-cost quality checks.

In contrast, the intricate nature of guidewire grinding projects within specialties like neurovascular applications introduces a higher degree of variability and demands more nuanced process control. This complexity requires continuous quality control protocols involving frequent checks and adjustments to maintain the stringent standards required. The dynamic nature of these projects means that quality control is not just a checkpoint but an integral part of the guidewire grinding process. For these specialized applications, the presence of advanced quality control capabilities and state-of-the-art quality machines on the shop floor is essential, demonstrating the CMO’s commitment to delivering parts that adhere to the highest levels of quality and reliability.

3. Technological Capabilities

Technological sophistication enhances the capability to meet the demands of complex guidewire and corewire grinding tasks. Simple, high-volume projects can be efficiently executed on older and less sophisticated machinery with higher operational speeds, offering a competitive advantage in terms of pricing. The ability to rapidly produce large quantities on rudimentary machines helps high-volume CMOs maintain a cost-effective edge.

However, the value of technological sophistication becomes evident when dealing with more intricate grinding tasks. Advanced machinery is essential when projects involve lengthy grinds and tight tolerance requirements. This sophisticated machinery can manage the intricacies and precision required for specialized applications, ensuring compliance with exacting standards. Understanding a CMO’s technological capabilities and primary focus is crucial before selecting a partner, as it directly impacts their ability to meet specific project demands, especially in the more complex segments of the guidewire and corewire grinding market.

4. Depth of Experience and Material Expertise

A guidewire grinding service provider’s depth of experience and material expertise is another crucial element. CMOs with diverse experience in the various aspects of precision manufacturing often have a deeper understanding of overcoming complex challenges than those with experiences limited to a specific niche. Their experienced engineers and technicians can offer insights and recommendations to enhance guidewire designs for improved performance and manufacturability. These CMOs often excel at overcoming unexpected challenges, ensuring projects stay on track. Additionally, their expertise in diverse bio-compatible materials, such as nitinol, stainless steel (SST), and titanium, enables them to provide solutions that meet the stringent standards of medical devices for strength, flexibility, and biocompatibility. Such comprehensive experience and knowledge in these materials promote the development of high-quality, reliable medical guidewires.

5. Communication and Collaboration

Effective communication and collaboration are essential for the successful development of any medical device. The ideal guidewire grinding service provider should be a partner in the development process, offering clear communication, transparency, and responsiveness. These attributes are particularly important for complex guidewire grinding projects because they enable the seamless integration of intricate design details, adapt to evolving project requirements, and address unforeseen challenges effectively. Collaboration from the early stages of design to final production ensures that the guidewires meet the specific needs of your medical device. This collaborative approach can lead to innovative solutions and improve guidewire functionality and manufacturability.

Crafting Precision: Specialized Solutions for Complex Guidewires

Selecting the right guidewire grinding service is a critical decision that impacts the quality and success of your medical device. Precision, quality focus, technological capabilities, experience, and collaborative communication are among the key factors to consider, especially when balanced against the complexities of the wire’s design. As a provider specializing in complex and intricate guidewire and corewire grinding, we understand the unique challenges of these projects. Our advanced technology, rigorous quality controls, advanced technologies, depth of expertise, and open collaboration ensure that each guidewire meets the highest standards of precision and performance, tailored to the specific needs of each medical application.

Are you starting a guidewire grinding project? Head to our blog to discover what you need to know before getting started. We also invite you to contact us to discuss your project requirements and how we can tailor our precision guidewire grinding services to meet your needs.