The Crucial Role of Corewire Grinding

Precision corewire grinding is an intricate process in manufacturing the building block of medical guidewires. This process enables the creation of ultra-thin diameters and intricate configurations used in life-saving procedures. This specialty medical wire is essential for providing a delivery platform through the body’s blood vessels for advanced neurovascular and cardiovascular interventions. The wire acts as a pathway for placing other devices, like stents, coils, microcatheters, flow diverters, and embolic coils to treat conditions like aneurysms and blood clots. A highly specialized manufacturing process ensures the accuracy, reliability, and performance of guidewires where precision can make a critical difference.

Precision in Corewire Grinding

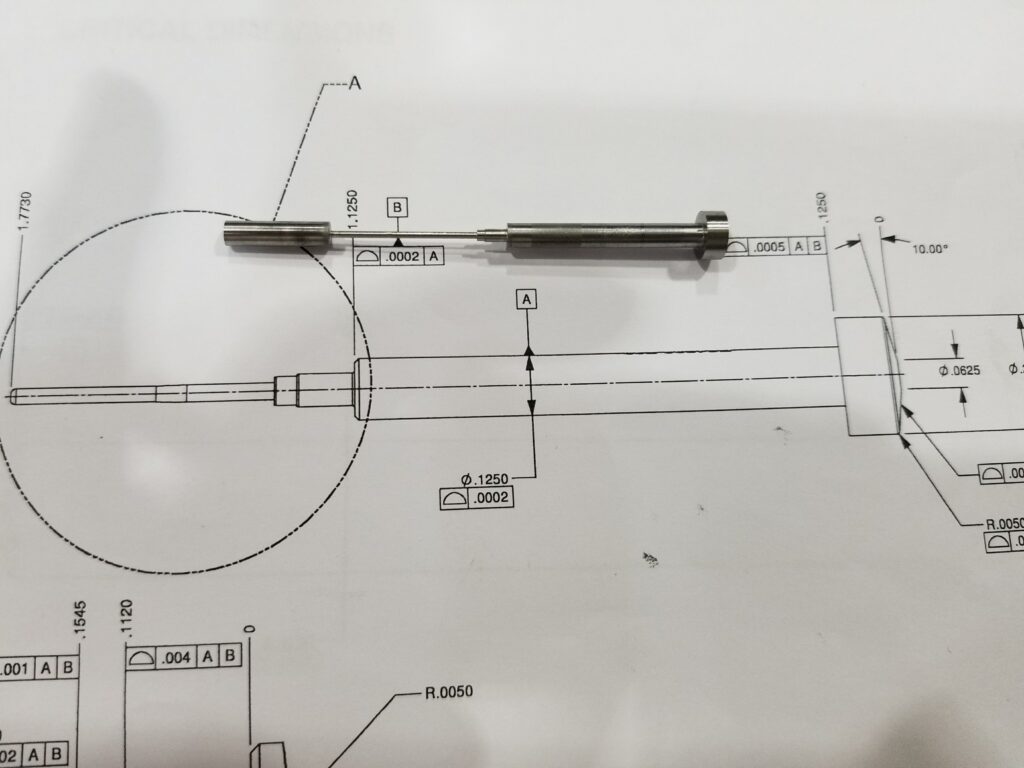

To achieve the desired outcomes, manufacturers rely on advanced technologies and skilled expertise to balance cost-effectiveness with exceptional quality. Given the vital nature of these components, corewire grinding is often a high-risk endeavor, demanding meticulous project management, skilled grinding technicians, and a deep understanding of the end application.

Whether manufacturing a corewire for enhanced strength or for complex medical devices, manufacturers prioritize accuracy and consistency at every step of the grinding process. This ensures that every product meets stringent industry standards.

Innovation and Challenges in Corewire Manufacturing

With innovation driving the medical field forward, corewire grinding remains a key aspect of modern healthcare, shaping the future of essential interventions.

If you’re overseeing a guidewire or corewire grinding project, this post aims to set you on the right course with seven helpful things to know before starting.

1. Choosing the Right Grinding Method

The complexity of your guidewire design determines the best grinding method:

Centerless Grinding: Ideal for simpler geometries, using wider grinding wheels for superior diameter control.

Outer Diameter (OD) Grinding: Perfect for intricate designs, employing narrower grinding wheels.

2. Leverage Design for Manufacturing (DFM)

Collaborating with manufacturers experienced in DFM can optimize your project:

- Enhances accuracy and efficiency.

- Reduces costs and expedites timelines.

- Ensures repeatable and reliable production.

3. Utilize Modern High-Tech Equipment

High-quality grinding machines are essential for achieving near-zero tolerances. Manufacturers equipped with cutting-edge technologies can handle intricate features and extremely small diameters.

4. Rapid Prototyping for Efficiency & Cost Saving

Technologies like on-site R&D capabilities can transform your engineering designs into physical prototypes quickly and cost-efficiently. Rapid prototyping enables quick transformation of engineering designs into physical prototypes, saving both time and money. It’s a critical step in testing and refining designs efficiently.

5. Rigorous Quality Management Systems

A robust Quality Management System (QMS) is vital for validating wire accuracy. Comprehensive inspections and advanced metrology tools ensure that your product meets all specifications. Ensure your manufacturer is ISO 13485 Certified and FDA Registered.

6. Communication is the Key to Project Success

Effective communication with your manufacturer ensures that all project requirements are met. Choose a partner who listens and adapts to your needs for a seamless experience.

These factors can shed light on the quality of your future experience with them – and the result.

7. Tackle Manufacturing Challenges

Innovative solutions can turn medtech manufacturing challenges into successes. For example, addressing tight tolerances, complex geometries, or tight schedules requires expertise and cutting-edge equipment.

Not all corewire grinding companies reach the same conclusion about the viability of a project. Seek out a manufacturer with the expertise, technology, and perseverance to develop innovative solutions.

Secure a Reliable Supply Chain & Scale Effortlessly

Partnering for Corewire Grinding Success

Achieving excellence in corewire grinding demands precision, advanced technology, and skilled expertise. By following these seven tips, you can ensure your project’s success while meeting industry standards.

Ready to Start Your Corewire Grinding Project?

Contact our medtech manufacturing experts to explore more tips and request a quote. Let’s collaborate to bring your innovative designs to life.