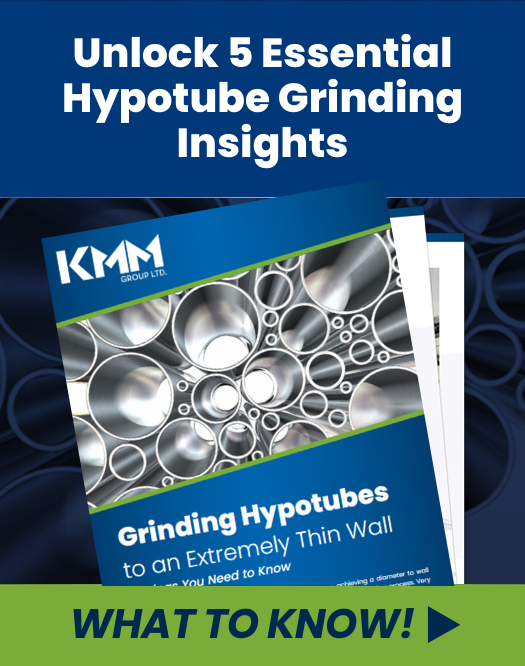

Choosing a Precision Grinding Partner

Choosing a precision grinding partner goes beyond reviewing a drawing and receiving a quote. Successful grinding outcomes are shaped early, during the first technical conversation, when material condition, tolerances, surface finish, and inspection requirements are evaluated before assumptions turn into risk. This early technical review helps sourcing and production teams protect cost, quality, and delivery once production begins.