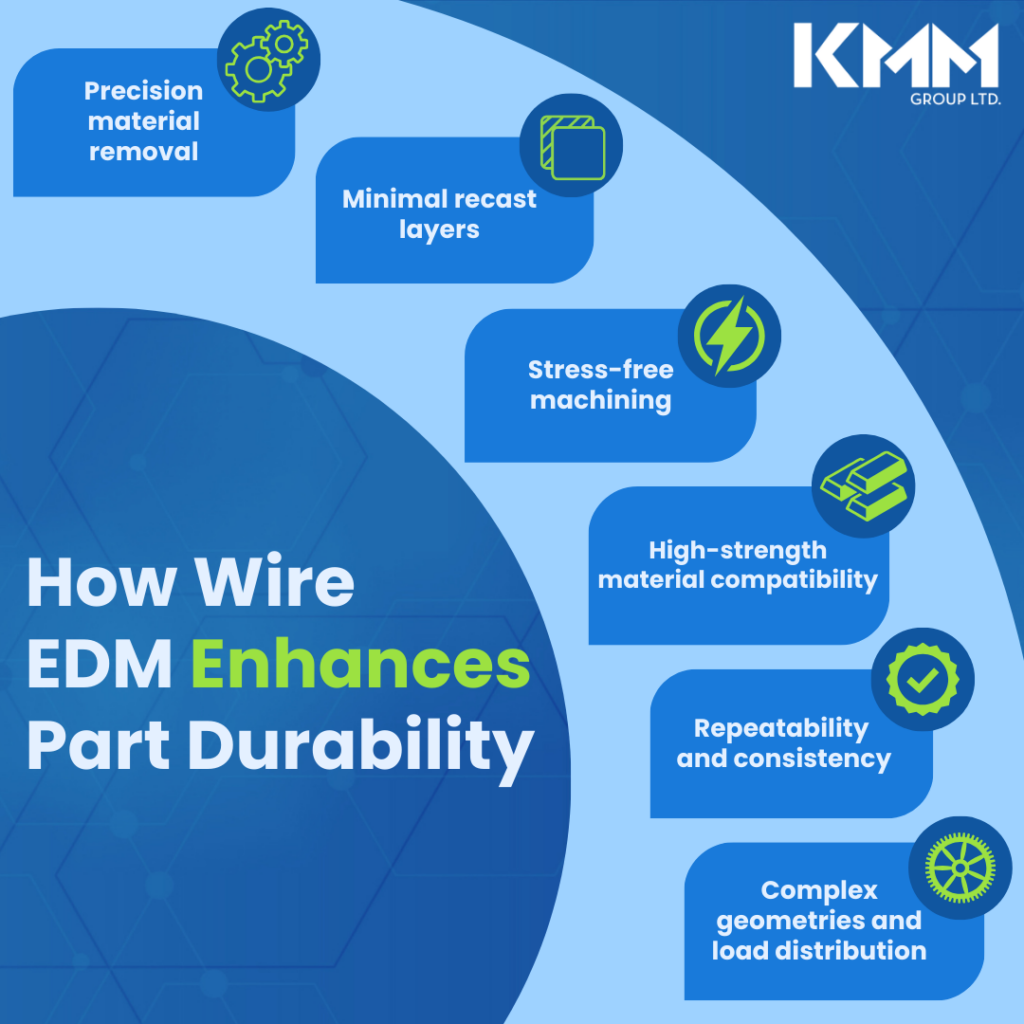

Building Tougher Components with Wire EDM

Producing strong and durable components is essential for the success and safety of critical missions and applications in fields like medtech, space exploration, and aerospace. When lives and investments are on the line, parts must be machined to endure the demands of a human body, the grueling conditions of space, or the high stress and […]

Wire EDM Success: How Material Compatibility Makes A Difference

Wire EDM (electrical discharge machining) is a specialized manufacturing process offering exceptional precision, complex geometries, consistent quality, quick turnarounds, and cost-effectiveness. Its easy setup, efficient programming, and ability to stack parts significantly reduce cycle time. The process is highly repeatable and can run for extended periods without inducing stress on the materials. This technology is ideal […]

5 Proven Benefits of In-House Custom Tooling & Fixtures

Many mission-critical components require custom tooling or fixtures, such as dies, jigs, and casting molds, to ensure they’re as precise as possible. However, some manufacturers cannot produce custom tooling and fixtures in-house. In this post, we’ll explain why in-house tooling and fixturing are essential for achieving the precision and cost-effectiveness you require. Whether using vertical […]

An Engineer’s Guide to Resolving Manufacturing Feasibility Uncertainties

Unchecked manufacturing feasibility uncertainties can throw a mission-critical manufacturing project off course, increasing the risks of project delays, unexpected costs, and late time to market. However, when your engineering design process includes protocols intended to reduce uncertainties before proceeding to full production, your machining and grinding projects have a much greater chance of success. This […]

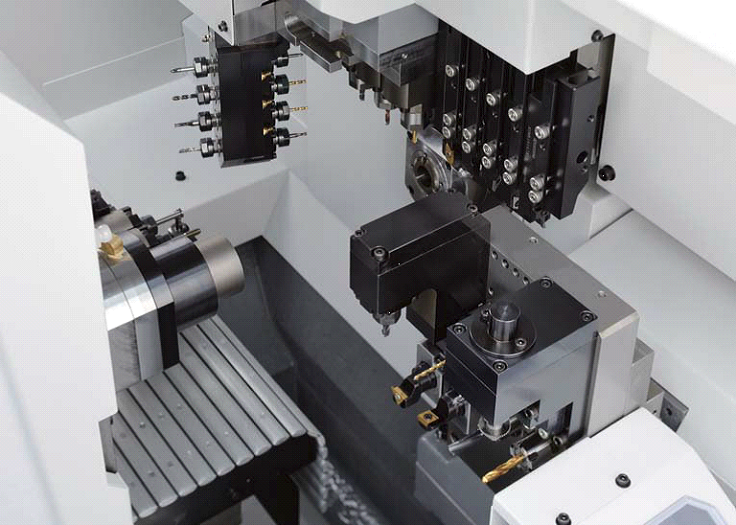

Advantages & Applications of 13-Axis Swiss Screw Machining

Swiss screw machining elevates the precision component manufacturing process with up to 13 axes, allowing endless possibilities. Using Swiss-type lathes with a turning center, Swiss screw machining first emerged in the Swiss watchmaking industry in the late nineteenth century. Later, Swiss screw machines evolved to become sophisticated enough to produce complex, high-precision components for today’s […]

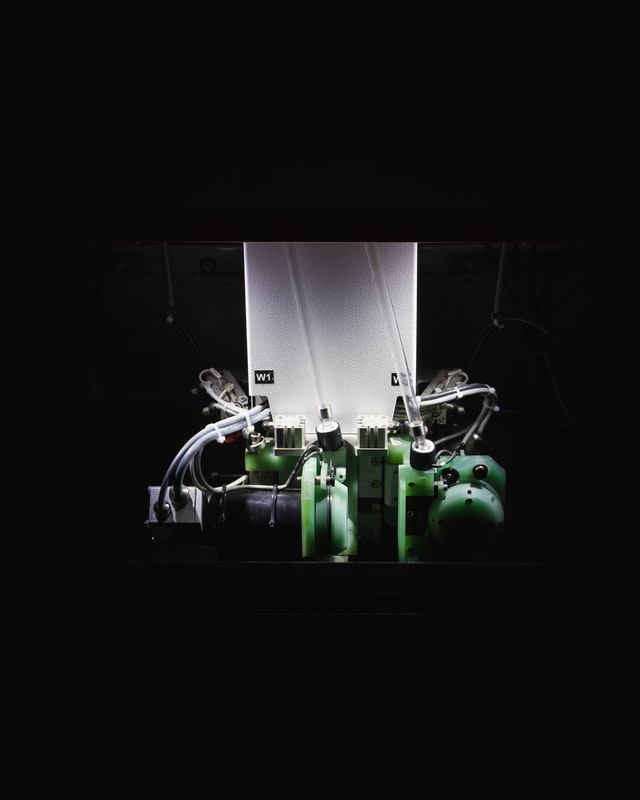

What is the Difference Between Wire and Ram EDM?

While the early concept of electrical discharge machining (EDM) dates back to the 18th century, modern EDM began in the 1960s with the emergence of the first wire electrode machines. Since then, EDM technologies have continually evolved to allow skilled craftspeople to machine precise and complex shapes that would otherwise be difficult to produce with […]

Is Your Defense Part Material Too Difficult to Manufacture?

Tight tolerances, thin walls, complex configurations, and visibly perfect finishes are among the chief defense manufacturing challenges. Still, nothing can ground a project liftoff faster than a difficult-to-manufacture part material. While straightforward materials like aluminum and stainless steel generally pose few complications, dozens of other exotic alloys can create significant obstacles on the production floor, […]

How We Pulled Off a Near-Impossible Aerospace Manufacturing Feat

We were instantly intrigued when our high-end motor manufacturing customer asked us to produce components for highly confidential defense motors. First, they explained that the tightly controlled tolerances prevented them from manufacturing these aeronautic parts in-house. Then, they revealed that more than 60 other component manufacturers had either refused or tried and failed to produce […]

How 5-Axis CNC Machining Can Produce More Powerful Race Engines

When 23-year-old rookie Austin Cindric ran a thrilling race to win the 2022 Daytona 500 in a wild finish, he debuted the new, highly anticipated NASCAR Next Gen race car. While the engine features the same pushrod V8 engines as outgoing NASCAR cars, one critical aspect changed: power. After a chorus of calls for more […]

5 Aerospace Component Manufacturing Challenges – and How to Solve Them

The aerospace component manufacturing process can present obstacles that delay progress and increase costs. In this article, we’ll cover the five of the most common challenges and outline helpful solutions to help you overcome them: Tight tolerancing R&D uncertainties Difficult materials Complex designs Missing tooling/drawings Continue reading to learn more about solving these common […]